Did you know there are around 30 different types of welding techniques requiring either gas as a welding source or an electric beam?

However, there are only four basic and the most popular types of welding processes that you need to know in detail. And these are the types we are going to discuss in depth.

So what is the welding process?

The concept of welding is a no-brainer. It’s simply the joining of two material parts together using a tool as a glue to affix them well.

Welding is a dangerous job and it can cause severe harm to the welder. However, if you are a little careful and fully equipped with welding essentials, nothing can harm you.

Let’s throw a light upon the most popular types of welding processes:

What Are The Four Main Types Of Welding Processes

Now that you know what does the welding process means, that is, the melting of base metals through an external source to recreate shapes and forms out of it, it’s time to learn about the different types of welding processes.

It is different from soldering and brazing in the sense that it requires the melting of the metals before joining the two parts together. To learn more about soldering check Welding vs Soldering.

So what are the four types of welding?

- Gas Metal Arc Welding

- Flux Cored Arc Welding

- Gas Tungsten Arc Welding

- Shielded Metal Arc Welding

Among these, Gas Metal Arc Welding is the easiest and most common type of welding. Moreover, each of these weldings requires you to wear a specific type of welding helmet, depending on the kind of material you have to weld.

Let’s discuss the four main types of welding in a bit more detail.

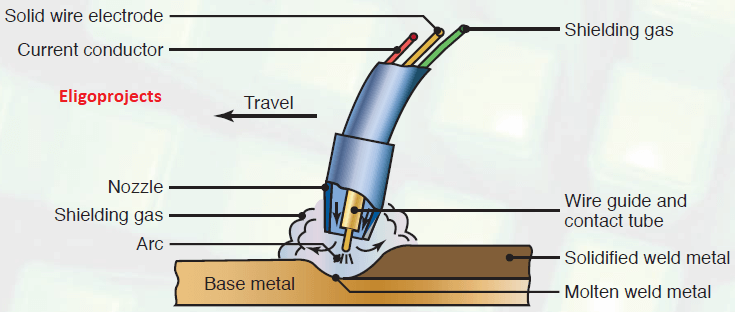

GMAW/MIG Welding Processes

Out of all the Major types of welding processes, Gas Metal Arc Welding is the easiest to learn and simplest to perform. Metal Inert Gas welding is another name for this type of welding, in which inert gases play a significant role.

Now the word Gas hints towards the need for shielding gas to protect the electrodes from the contaminated atmosphere.

A welding gun for feeding the wire and welding material are the two electrodes that welders use for MIG welding. These two electrodes connect to form an arc, which then runs the whole welding process.

MIG welding also requires a current and voltage as a secondary source for welding materials. This type of welding is ideal for welding materials like stainless steel, copper, nickel, aluminum, etc.

As we already mentioned, GMAW is the easiest to learn and control, which means, beginners can make the most out of this type before moving to advanced options. Moreover, MIG welding fits best for welding hobbyists and a few automotive industries.

However, each type of welding has its downside. That being said, GMAW is not suitable for welding thick materials like ferrous. For such materials, you will want to switch to other types of welding that can do the job faster and better.

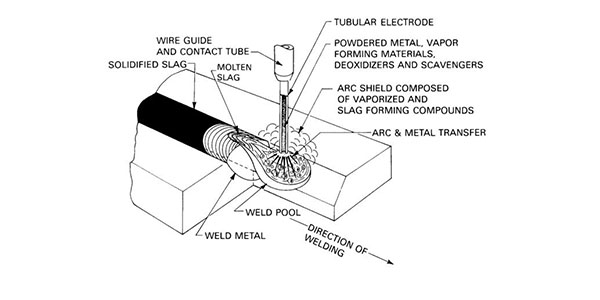

FCAW Welding Processes

Flux Cored Arc Welding is the second most common type of welding with the simplest technique. It is more or less similar to MIG welding, only that in this type there is no requirement of Gas as an external source to protect the arc.

It is similar to Gas welding in a way that both these types of welding processes are auto-fed. However, Flux Cored Arc Welding has a flux fit inside that does the job of shielding gas.

Hence, this can be done outdoors unlike gas arc welding that is specifically for indoor projects.

There is another important advantage of Flux Arc Welding over Gas welding and, that is, with this type of welding process, you can fix heavy metals very well, like ferrous.

Similar to Gas welding, this process is easy to learn, ideal for beginners, and DIY savvies, so you can use it for small home-tasks. However, its semi-automatic arc provides high-grade welding speed, thus, it is also used for construction purposes in industries.

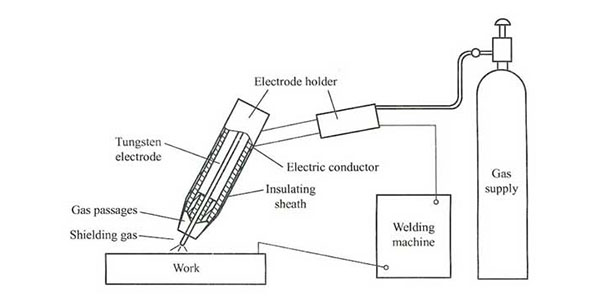

GTAW/TIG Welding Processes

Gas Tungsten Arc Welding is the most interesting and toughest type of welding process out of all other types of welding.

This type of welding is done for stainless steel and non-ferrous materials like gold, brass, lead, copper, nickel, and almost all the materials if you know the trick. Hence, TIG welding is the most versatile type of welding and has a broad usage in the Industry.

TIG or Tungsten Inert Gas welding is another name for GTAW. As the name implies, this type of welding uses a tungsten electrode and needs a continuous gas supply, like Argon, helium, or both.

Here is how you can weld using the TIG technique:

First, a torch head with tungsten is used to produce the Arc for welding. Then the same torch provides the shielding gas and protects the arc.

Once the base metal is melted, the welder has to manually introduce a filler rod to complete the process. It has a high welding speed, hence it is used in welding bicycles and Aircraft.

You require the skill to master this welding process and it takes a lot of time to be an expert. But you will be impressed by the quality results and splatter-free surface after the whole process is completed!

Note: The Arc produced during the welding process is very dangerous. We always recommend you wear an Auto-darkening welding helmet during the intricate projects.

The Gas Tungsten Arc Welding is famous for producing THE best results with zero flaws and a mess-free surface. That is why you need to work really hard to master this process of welding. And it is certainly not recommended for beginners.

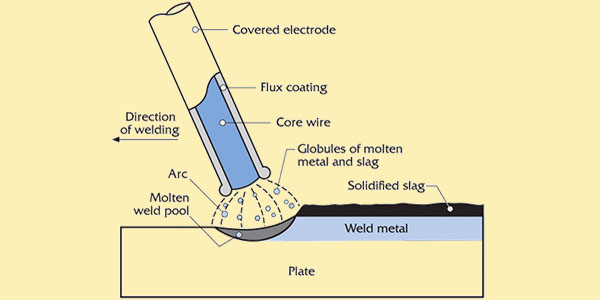

SMAW Welding Processes

Shielded Metal Arc Welding, better known as Stick Welding; this type of welding process is the simplest of all, though not easy.

As the name suggests, Stick Welding is an old-fashioned style of the welding process. In this type of welding, the welders use a stick-like object to weld the materials.

And that is exactly what makes it the most inexpensive method of welding. Plus, the same quality makes it ideal for home-shop welding as anyone can afford the materials required for Shielded Metal Arc Welding, unlike the other types.

This process is inexpensive, though most of the automotive industries still do not perform this in their work field.

But given that it can produce an Arc and weld the materials perfectly well, the welding hobbyists and dads who like to do everything themselves can opt for Shielding Metal Arc Welding.

The word Shielding means it’s already shielded. This means it requires no extra gas to protect itself from the contaminated air.

Hence, it can be done outside and in the toughest of environments. Plus, this type of welding process is even suitable for rusty and dull materials.

Now as we said, each side has its drawback and the same goes for stick welding as well.

This type of welding does not give quality welds. This means, after welding the materials, you will not find the furnished look like in TIG welding.

It leaves cracks and pores in the welded materials. Therefore, this type of welding is not very durable. Hence, it is not used in construction industries.

Other Types Of Welding

This flowchart pretty much sums up all the other types of weldings.

They are not widely used in the welding field. Besides, they are all very similar to the four most popular types of welding, so you don’t need to go into too much detail. We have listed down the other types below.

- Energy Beam Welding – it gives very precise results.

- Atomic Hydrogen Welding – it is similar to TIG, only that the shielding gas is Hydrogen.

- Plasma Arc Welding – this process is similar to MIG welding, the only difference is in the torch.

- Electro-slag welding – it was popular in the mid-1950s and was used for welding thick-steel metals.

FAQs

Conclusion

Now that you know what are the four types of welding processes, and what importance each one has in the industry, you might as well decide which one will suit your project.

If your task revolves around welding thin materials, and you are just beginning to learn the process of welding, go for MIG welding. And once you have mastered every process, step up to TIG welding.

Hopefully, we have cleared all your queries about different types of weldings and you are all set to enroll in a welding project.