Are you a beginner in the field of welding? Do you want to learn the difference between welding, soldering, and brazing? We hear you!

These three terminologies though are very similar to each other, but a minute difference between them sets them apart. And only a few know to use the right method at the right time.

First, keep one thing in mind, the three methods, that is, welding, soldering, and brazing help in joining the two pieces of metals together. Plus, all three of them require heat to melt the metals.

So how do you differentiate between them? What is the difference between welding, soldering, and brazing? What is welding and what is soldering? We will discuss them all in detail.

Note: Remember to wear proper gear like Gloves, Welding helmets, and Safety Goggles to protect yourself from flying objects, fire, and molten metal.

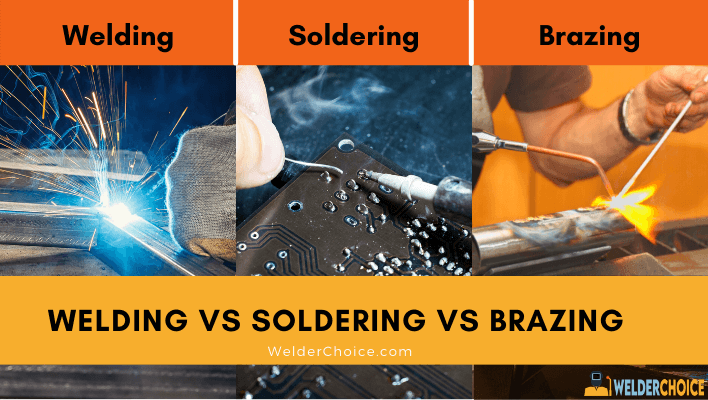

Welding Vs Soldering Vs Brazing

The main difference between each of them is in the temperature. Welding requires the highest range to melt the metals. Whereas, for soldering and brazing, we use a temperature lower than that for welding.

Now to know what is the difference between welding, soldering, and brazing, you must first have a clear concept about each of these methods.

Let’s dive into the details!

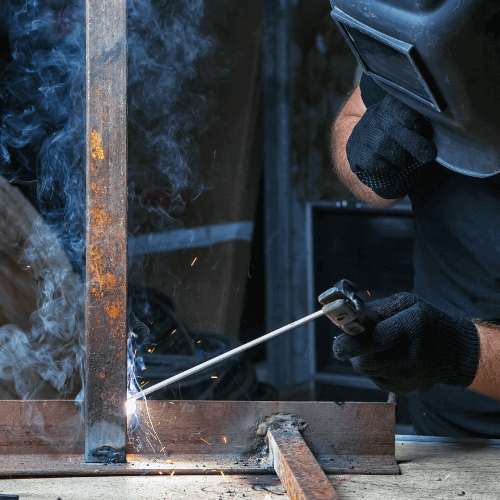

What Is Welding

Welding is the joining of two metals by applying heat, pressure, or both on the base metals. After the metals are in their molten state, they are allowed to cool down till they fuse completely.

In welding, the fusion is done between two similar metals. For example, you can only fuse copper with copper, or steel with steel. You can not join copper with steel.

In the Industrial world, there are around 30 different types of welding. However, Industries today only use the four most common types of welding.

One most important thing to consider while welding is the temperature range. Unlike Soldering, the process of welding uses a high-grade temperature (above 840-degree Fahrenheit) to melt the selected metals. And it can be as high as 10,000-degree Fahrenheit.

Note: You must carefully adjust the temperature. If it gets too high, it will change the natural property of the metal, resulting in the weakening of the used metal.

The best way to check whether the metal is properly weld or not is to compare it with the unwelded part. If they both look similar to you, you have done a great job. But if you were not careful before, you will find them weak in strength.

Now as the process of welding starts, you will have to face the constant splatters, heat, and Arc. That is why welders usually wear an auto darkening welding helmet to save themselves from any injury.

Moreover, the one advantage of welding over soldering and brazing is, welding creates the strongest bonds. Whereas, soldering and brazing do make permanent bonds, but they are weak in comparison with the welded joints.

Furthermore, some metals need a manual introduction of filler materials to fill the small gaps. So you will have to watch out for that too.

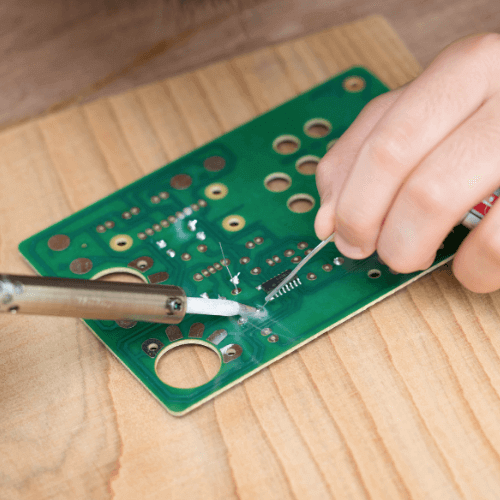

What Is Soldering

This process is similar to welding in the sense that the fusion of two metals takes place by applying heat. However, the fusion is between two different metals, and the base metals are not melted in this process, unlike welding.

According to the American Welding Society, soldering is a liquid-solid type of bonding technique.

In the liquid-solid type of fusion process, we melt the filler metal which denotes the liquid phase. And the workpieces, that is, the base metals remain in their solid-state denoting the solid phase.

That being said, in soldering, welders melt the filler metals at a temperature below 840-degree Fahrenheit which is lesser than welding.

Note: In welding, we mentioned filler materials, but usually we melt only the target metals for fusion. But in soldering, it is important to melt the filler material and use it to join the other two metals.

Now as we said, you can fuse two entirely distinct metals using solder. For example, copper, brass, iron, gold, aluminum, etc can be soldered to develop strong and permanent bonds.

Furthermore, soldering has two popular types namely, Iron soldering and wave soldering.

- Iron Soldering involves the use of iron with a copper tip that transfers heat to the joint, and eventually mends the bond. Plus, it is the oldest and simplest type of soldering and has been helping the workers in making permanent connections between the electrical devices for a long time.

- Wave Soldering is used to manufacture Printed Circuit boards. As the name suggests, in wave soldering, a pump produces standing waves that solder the components of the board.

What Is Brazing

The process of Brazing is more or less similar to soldering, except for the requirement of temperature. Besides, brazing is best to do when you have to join small or thin pieces of metal.

Brazing also comes under the category of liquid-solid phase techniques, in which the filler metal melts to join the two metals together. Whereas, the base metals are not melted and remain in their original solid-state.

In this fusion process, the filler metal melts at a temperature above 840-degree Fahrenheit but not as high as the temperature in welding. This is because the filler metal has a lower melting point than the base metals.

Furthermore, like soldering, brazing binds the two dissimilar metals together and makes a bond stronger than that of soldering. Hence, it is useful in joining the metals that solder can not work on.

One most important thing to remember is that brazing uses a Flux solution to heat and join the metals with the help of filler material. The flux produced in brazing has the following advantages:

- It protects the filler metal and allows it to flow by capillary action by bringing it up to its molten state.

- The flux helps prevent oxidation by removing the oxides.

- It promotes wetting which helps the filler metals to layer around the target metals.

There are many forms of Fluxes ranging from powdered form to liquid and solid states. Using the flux is a very crucial step in blazing and soldering and it eases up the whole process of fusion.

Welding vs Soldering

The one major factor that differentiates welding from soldering is a huge difference in the range of temperature.

As we mentioned above, welding heat up the base metals and melts them at above 840-degree Fahrenheit.

On the other hand, the temperature is extremely low in soldering as compared to welding, that is, below 840-degree Fahrenheit.

Moreover, as we already know, soldering uses filler metal in the form of a reel or tube, unlike welding that uses guns or nozzles to melt the metals.

Another Major property that contradicts soldering from welding is that the soldering usually involves projects related to electronic devices. While welding is mostly done in Industries to weld Aircraft, pipelines, railroads, automobiles, etc.

Welding vs Brazing

Welding and brazing have many similarities. For instance, both processes include heating the metals to join them together. So what is the difference between welding and brazing? Let’s find out!

The main difference is between the temperature, as we have already stated. Welding is done under temperatures higher than brazing.

Furthermore, the very basic difference is in the melting equipment. Brazing includes the melting of filler material. While in welding, you have to melt the edge of target metals to form joints.

As these processes create sparks, you need to wear different types of welding helmets to protect your eyes from extreme brightness.

Another huge difference between welding and brazing is that when you have to join two different metals together, you braze it. Whereas in welding, we fuse two similar types of metals.

Soldering vs Brazing

Soldering and brazing are very similar to each other and there is hardly any difference between the two.

However, brazing produces better results and creates stronger bonds between the metals than soldering. To tell the truth, soldering forms the weakest joints among the three different types of fusion processes.

Furthermore, brazing uses a higher temp than soldering, that is, above 840-degree Fahrenheit.

Both the methods use Flux to promote the capillary action but Fluxes are typical for brazing as compared to soldering.

FAQs

Conclusion

To sum it up, Welding is the most common method used in Industries, and it uses the highest temperature among all. On the contrary, Soldering is done mainly to fix printed circuit boards. And Blazing can mend the small joints that soldering can not.

So that was all about it. Hopefully, you have your answer to the question about the differences between welding, soldering, and brazing.

Make sure you have all the necessary pieces of equipment for whichever type you are opting for. And always leave room for learning before you sign up for a project!

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.