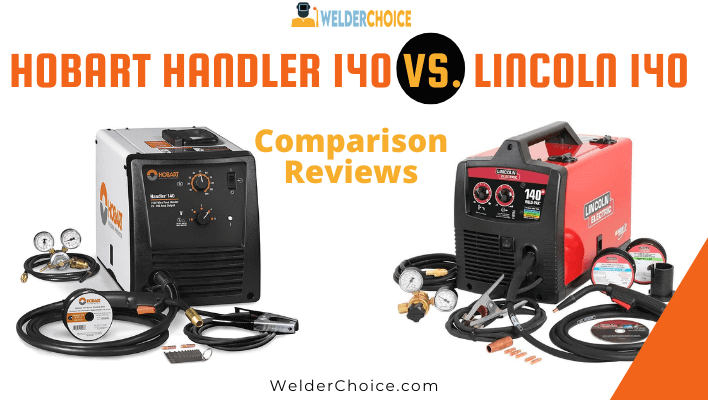

We’ll compare the Hobart Handler 140 Vs. Lincoln 140 in this article to find which one performs best.

The company that makes the Hobart Handler 140 and Lincoln 140 is renowned for producing top-notch welding equipment. Both types of machinery come with enticing features that are easy to use and draw in customers. Here, we’ve compared the Hobart Handler 140 and Lincoln 140 so you can get the equipment that best suits your requirements without being confused.

What Is In Hobart Handler 140?

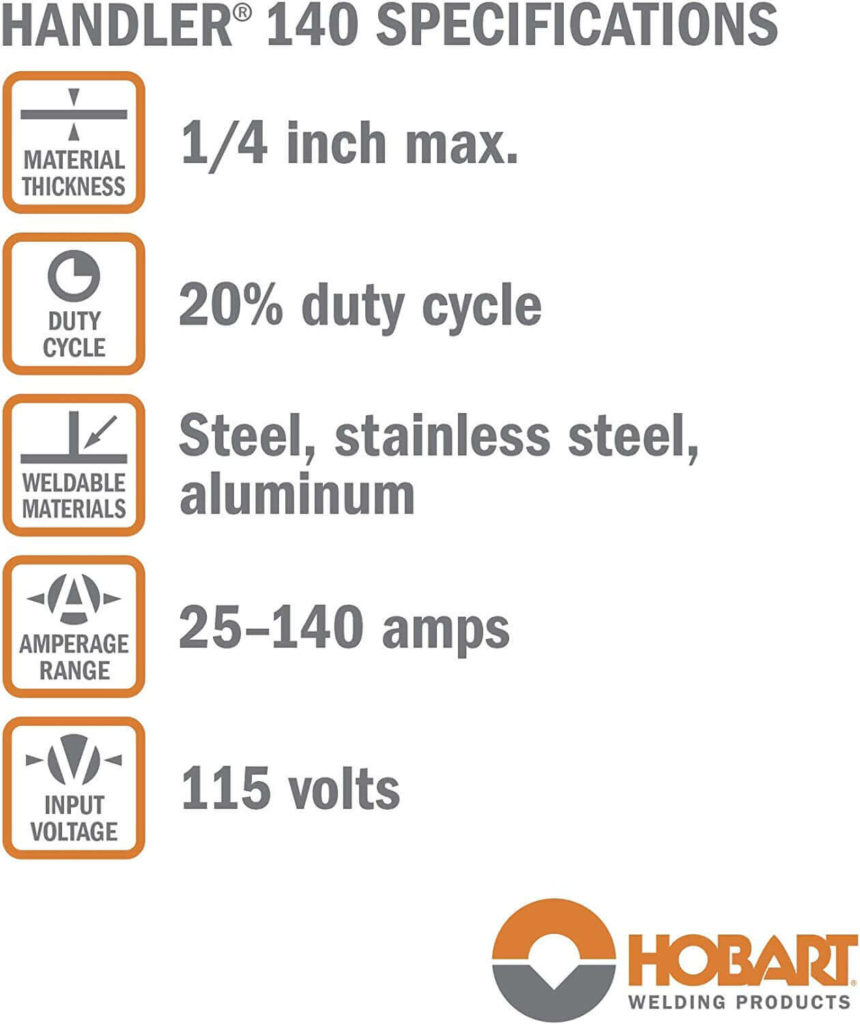

The Hobart Handler 140 is the second-smallest MIG or Flux-cored gear unit under the Hobart brand, making it the perfect tool for DIY and home improvement jobs. The apparatus is light and portable, weighing around 57 pounds, and it runs on 110 volts of input voltage.

It has an internal contractor that maintains the electrical cooling of the wires while the machine is running. Metals of a one-quarter inch thickness can be welded using this machine. Drive rolls have double, knurled, and smooth grooves that make it simple to change wire diameters. This prototype is built with numerous safety features, such as an automatic reset heat mechanism that guards against heat overload and motor damage.

When Should I Use Hobart Handler 140?

The Hobart Handler 140 is a superb option for repair, upkeep, and minor building tasks around the home, ranch, and farm, including plumbing and particular automotive repair operations, etc. The MIG cannon is 10 feet long, so you don’t need to move the machine around. The output amperage ranges from 25 amp to 140 amp at its maximum. This equipment has a five-position voltage setting, giving you better control over the ARC length for light welding applications.

Pros And Cons of Hobart Handler 140

Pros

- It offers quite a few features and functions for lightweight gear on a 110-volt outlet, making it appropriate for enthusiasts and beginners.

- Hobart 140 provides an actual piercing and arc achievement while producing noticeably fewer welding sparks and splatter.

- It has a twofold processing capability, enabling it to function effectively with various metal types and densities.

- The simple installation procedure helps you save a lot of time and work.

Cons

- It is only appropriate for little undertakings; using this equipment to complete heavy-duty work could provide difficulties.

- For MIG welding activities, you will require a separate gas cylinder purchase.

What Is In Lincoln 140?

Welders that do their own work are known for using Lincoln 140. There are no amp options and only four voltage settings are available. The 10-foot cable length lets you roam around without restriction. This includes a spool gun, a regular and gasless gas nozzle, a regular and gas hose, and other equipment.

It only weighs roughly 50 lbs, requires 120 volts of input voltage to operate, has an amperage range of 30 amps to 140 amps, can weld up to a thickness of 3/16 inch, and can feed wire at speeds ranging from 50 IPM to 500 IPM. Despite being a small machine, it has the ability to weld aluminum, stainless steel, and thin steel. Flux-cored welding is also used to weld thick metals.

When Should I Use Lincoln 140 welder?

The Lincoln 140 welder is most frequently used for home tasks, as well as for repairs and maintenance on farms and ranches. It is appropriate for light to medium welding applications. It is well-known that this equipment can help you with your regular welding needs. This Lincoln 140 is the best option if you require a machine that works with a variety of spool gun types and effectively performs flux welding without the use of gas. It is equipment that is suitable for beginners because it includes improved safety features. This welder’s straightforward and user-friendly design is built to maximize user ease. Technical issues won’t arise when you become familiar with the tool.

Cons and Pros of Lincoln 140 Welder

Pros

- Installation is simple.

- It includes a spool gun that makes welding metal easier. Additionally, it offers several nozzles.

- It alerts you when the machine becomes too hot; this feature can stop potentially harmful situations from happening.

- This machine includes safety eyewear and gas shields, so you don’t need to buy them separately.

Cons

- The use of a spool gun is required for welding aluminum.

- If you want to mobilize it around smoothly without unneeded jerks, you need a rolling cart.

Main Difference between Hobart Handler 140 Vs Lincoln 140

- Below are the differences between the Hobart Handler 140 and Lincoln 140

- Lincoln’s wind feed velocity range is 50 to 500 IPM, whereas Hobart Handler’s range is 40 to 700 IPM, proving that Hobart 140 is more adaptable.

- Lincoln only offers four heat levels, but Hobart has five adjustable voltage controls.

- Hobart’s gas supply can handle pure argon or argon-containing mixes. Lincoln runs entirely on C02.

Conclusion

We can see from this comparison of the Hobart Handler 140 vs Lincoln 140 that both machinery types are exceptional. Since you buy the equipment depending on the project you’ll be working on, it’s impossible to say which system is better. However, Lincoln 140 is acceptable whereas Hobart Handler 140 is not appropriate for welding aluminum. It might be said that the Lincoln 140 is the better equipment of the two for this specific reason. If you frequently use aluminum metal in your projects, it’s important to be aware of this fact.

FAQs

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.