The .030 vs. .035 Flux Core Wire will be compared in this post to find which one performs better.

Finding the wire that is the proper size for you when welding is a difficult undertaking. In order for you to buy the straight flux core wire that best suits your needs, we have compared .030 and .035 flux core wire here.

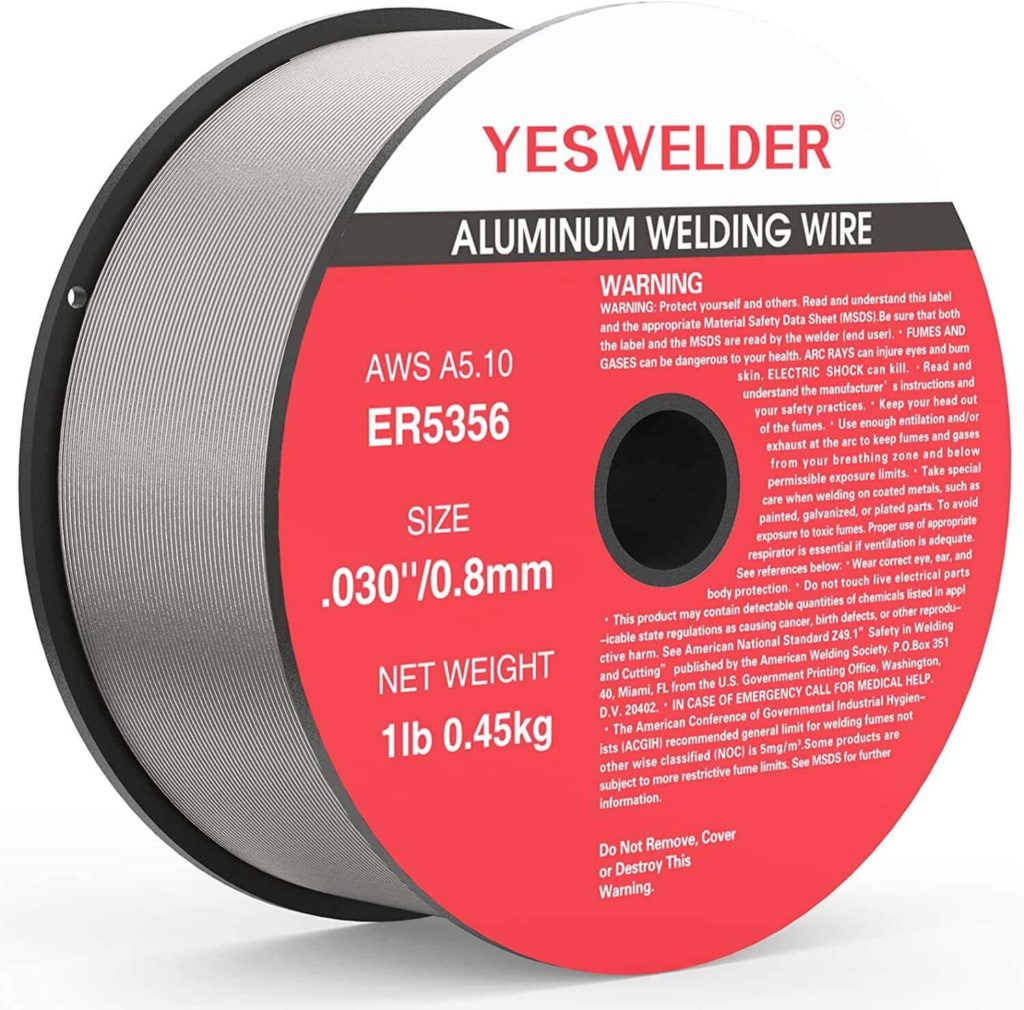

What Is a .030 Flux Core Wire?

The .030 Flux Core Wire is a welding wire with a core formed of flux, as its name would imply. The diameter of the welding rod is indicated by the number .030″ in the product name.

Since the .030 Flux Core Wire is thin and can only operate with thin metal sheets, it uses less amperage. When welding thick metal sheets, .030 Flux Core Wire encounters difficulties. There is no need for external gas tanks with this flux core wire.

When should you use .030 flux core wire?

The finest choice for working with light metals and thin materials is .030 Flux Core Wire. When welding gas is not necessary for your procedure or is not available, you can utilize this wire.

Pros and Cons of .030 Flux Core Wire

Pros

- After welding, much less cleaning is necessary.

- .030 Flux Core Wire operates without any jerks or malfunctions at all.

- It produces a great deal less pollutants and smoke.

Cons

- The only thin metal sheets that .030 Flux Core Wire can weld.

- Due to its small diameter, it can burn hotter and cause deeper holes in metal.

Recommended Post: Best Flux Core Welder

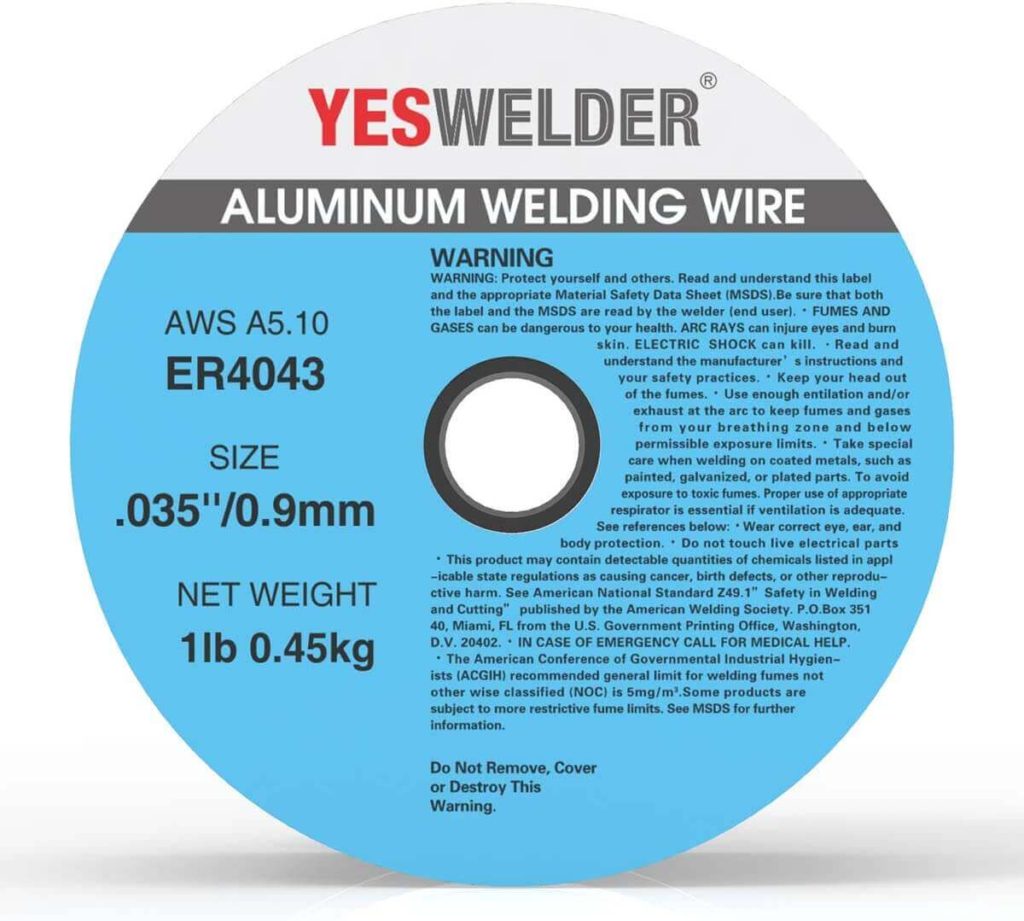

What Is a .035 Flux Core Wire?

0.035 Flux Core Wire is a welding wire, just like 0.030 Flux Core Wire. It has flux in the core, which when melted can provide filler metal for a clean welding process. The welding rod diameter is indicated by the prefix.035 used in the product name.

Because it is thick and burns at a very high temperature, .035 Flux Core Wire requires a lot of amperage and performs better and deeper piercings.

When should you use .035 flux core wire?

You must reduce the wire speed and raise the voltage in order to use a .035 flux core wire. On large metal sheets, it operates without a hitch. It can be used with or without gas. If you don’t use gas, it splatters, but gas makes it work flawlessly.

Cons and Pros of .035 Flux Core Wire

Pros

- It is primarily capable of welding carbon steel and other heavy metals.

- This wire produced very little slag, which is readily cleaned off.

- Due to its quick freezing quality, it may work satisfactorily even in a moderate wind situation.

Cons

- It does not perform cleanly unless you are using gas.

- Only metals with a thickness of 1/4 inch can be processed smoothly.

Main Difference between .030 vs. .035 flux core wire

The following are the differences between .030 vs. .035 flux core wires:

- The approximate welding range for .030 Flux core wire is 50 to 150 Amp, and for .035, it is 75 to 200 Amp.

- For .030 wire, the voltage range is approximately 15 to 17 volts, and for .035 wire, it is approximately 15 to 18 volts.

- 80 to 445 inches per minute is the range for .030 wire’s wire feed speed, while 70 to .305 inches per minute is the range for .035 wire.

- For piercing thin metal sheets, .030 wire is appropriate, however .035 wire is better suited for thick metal sheets, which are 1/4 inches thick.

Final Thoughts & Recommendations

Since the wire you choose depends on the metal you’ll be welding and the machine you’ll use, it is impossible to compare which wire is superior. Which wire is superior cannot be said with certainty.

Heavy metals are best welded with .030 wire, which is appropriate for novices or general welding jobs.

FAQs

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.