Usually, many of the products created in the United States need welding. The term “welding” can, however, refer to a wide range of metal-joining procedures and devices. When there are more than 30 different welding processes to select from, it’s easy to become perplexed.

Until the end of the nineteenth century, when arc welding and oxy-fuel welding became widespread, forge welding was the only technology used. Global warfare in the early twentieth century encouraged the development of new welding technologies that were both cost-effective and durable.

Simple manual processes like shielded metal arc welding (SMAW) were developed and are still used today. As a result, gas metal arc (MIG) welding and flux-cored arc welding (FCAW) were developed.

In the latter half of the twentieth century, laser beam welding and robot welding, both of which are used in industrial settings, continued to enhance welding technology.

Today, we’ll look at seven different industries that use welding in various forms to focus on these industrial environments. However, as you’ll see, MIG welding is the industry standard across the board.

7 Welding Industries

Here we listed the 7 Welding Industries that are used world widely.

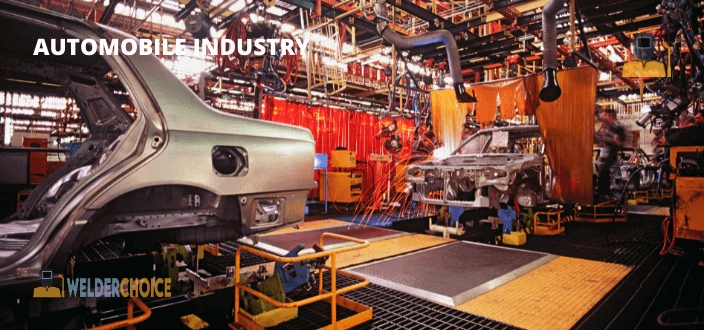

Automobile Industry

MIG welding is ideal for joining aluminum sheets on the manufacturing line because it creates a super-strong bond even between thin metals. Laser MIG welding is gaining steam as vehicle manufacturers recognize the cost-effectiveness of this method, which also delivers greater penetration depth.

Welding will continue to be a crucial aspect of the automotive industry unless things significantly change. The average automobile requires thousands of welds.

Rail Tracks

Welding is very important in the railroad industry. When steel rails were initially introduced more than a century ago, welding was required to link them together. In 1932, an innovative method of spot welding called shot welding was developed to efficiently fuse this steel together.

The Pioneer Zephyr, America’s first diesel streamline train, was manufactured by the Budd Company, which invented shot welding. One of the first examples of spot welding in action was this gigantic metal beast.

Aerospace

Welding is one of the most effective methods of melting metal, so it’s no wonder that it’s widely used in the aircraft industry. In actuality, aerospace engineers utilized welding to build the first commercial aircraft.

Gas welding was once the industry standard, and it’s still utilized for aircraft maintenance today, but electrical arc welding has taken its place. This process can be used to replace almost any sort of metal.

TIG welding, which was first used in the aerospace industry to work with magnesium, became popular in the 1940s.

Engineers are increasingly using MIG welding to build airplanes, whereas plasma arc welding and electric resistance welding are commonly employed to join sheet metal and perform precision work.

Infrastructure and Construction

MIG welding was developed to connect non-ferrous metals such as aluminum. Construction workers, on the other hand, usually work with steel, and MIG welding is widely utilized in steel activities.

On-site welding is in high demand because over half of all steel manufactured is used in the construction of commercial and residential buildings. Welding is a fantastic technique for repairing damaged machinery or broken tools, as well as for construction.

Flux-cored welding is also widespread in the construction industry, and shielded-metal arc welding is a messy but cost-effective option. Plasma arc welding is perfect for intricate precision work.

Wholesale Trading

While it may seem unusual for a professional welder to engage in wholesale, many do. Companies that offer welding goods and equipment are in great demand for welders who are educated about the items for sale and can provide expert guidance to both private and business clients.

In addition to a welding degree, a welder who wishes to work in this industry needs complete marketing studies. Because a salesperson must be aware of many types of welding methods and the machinery used to weld specific metals, a good understanding of welding is essential for work in this area.

Manufacturing

MIG welding is also utilized in the mass production of a wide range of products, including computer components and industrial coils. Because of its speed and cost-effectiveness, it’s the ideal answer for high-volume manufacturing.

As we’ve just seen, MIG welding is extremely adaptable. MIG welding is particularly important in the manufacturing industry since it permits a large range of metals to be used. Manufacturing is responsible for 60% of all welding jobs.

From furniture to agricultural implements, computer parts to mining machines, anything that is put together on a production line will require welding at some point.

Shipping

Most ships, from cruise liners to large tankers to cargo ships and aircraft carriers, are built with welding. Rivets can also be used by engineers, but welding is more efficient.

Since WWII, welding has been the gold standard for speed and economy in the shipping industry. Welding, like in the construction industry, is a standard method for repairing ships of all shapes and sizes.

Conclusion

These welding industries experts have volunteered their decades of experience and knowledge in order to shed light on the industry’s current and future state.

They all agreed on the industry’s strong pulse, which they attributed to a booming economy and new technological developments. Section 232 tariffs were also highlighted by the majority as a significant impediment.

However, the most pressing problem in welding is the scarcity of qualified welders. Despite this reality, numerous respondents expressed hope that attempts to lure young people into the industry will pay off in the long run.

Overall, they stated future that, despite current obstacles, the welding industry will continue to develop.

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.