MIG Vs. TIG Welding: What’s the Difference? to know go through this article.

In the welding industry, MIG and TIG are two prevalent welding methods with similar-sounding names.

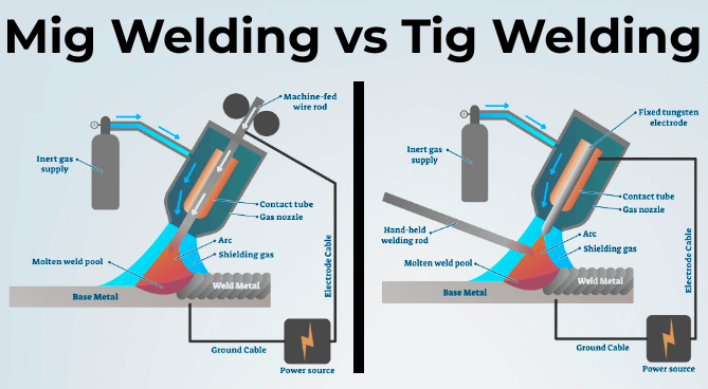

While there are some parallels between the two welding techniques, they are not identical. An arc and a shielding gas are used in both.

The main difference between MIG and TIG welding is the electrode used to create the arc. MIG welding uses a consumable solid wire that is machine fed to the weld, whereas TIG welding uses a non-consumable electrode. In TIG welding, a hand-held filler rod is typically utilized to make the connection.

Understanding how MIG and TIG welding function and where they shine will help you become a better welder.

MIG and TIG Welding: What’s the Difference?

MIG Welding

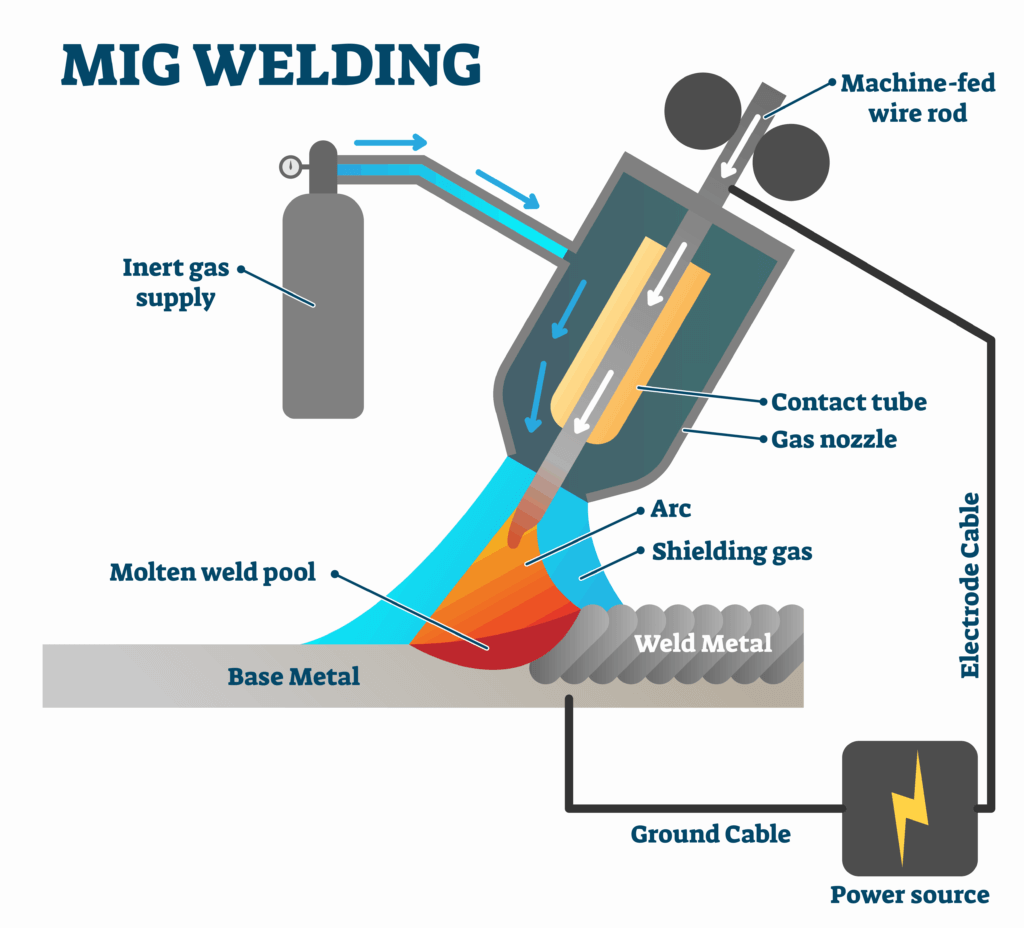

There are a few abbreviations for this well-known process. “MIG” is the most commonly used abbreviation for metal inert gas. Some individuals, on the other hand, refer to it as gas metal arc welding (GMAW).

When detailing the MIG process, it’s easy to get carried away. In contrast, MIG welding uses a semi-automatic or automatic arc to weld.

A continuous, consumable wire electrode is also utilized, as well as a shielding gas, both of which are provided to a welding gun via a lead (sometimes called a torch).

Because the wire electrode also serves as a weld filler material, the wire diameter and composition will vary. The type of metal, its thickness, and the placement of the joints all have an impact on which procedure you use.

The solid electrode wire is fed from the MIG welder to the torch, where it is consumed on various sized spools. As a result, the wire feed speed (WFS), which must be adjusted to provide the right quantity of weld metal for the joint, is one of the most critical MIG welder settings.

Furthermore, the shielding gas used is often a mixture of 75 percent argon and 25% CO2. This combination promotes weld penetration while reducing bead porosity. The shielding gas, on the other hand, varies depending on what you’re welding and other variables.

Additional information about MIG welding can be found in my post on the technique.

TIG Welding

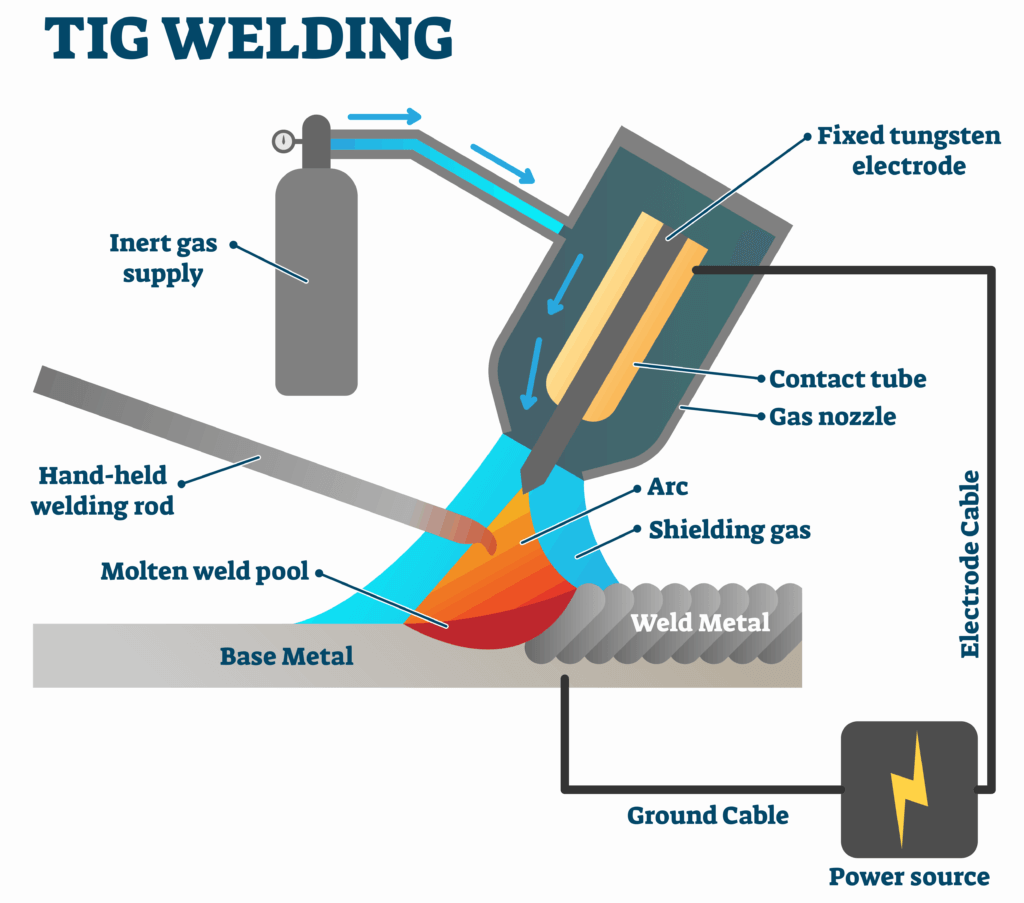

Tungsten inert gas (TIG) welding is also known as gas tungsten arc welding (GTAW).

In the TIG welding technique, an arc is also used. MIG welding, on the other hand, is distinguished from TIG welding by the use of a non-consumable tungsten electrode and a separate consumable filler material.

With your second hand, manually feed a “rod” of filler material into the weld puddle as the non-consumable tungsten electrode forms an arc.

The TIG filler rod’s composition and size will vary depending on the type of weld you’re doing, just like the consumable MIG wire electrode.

Rather of the argon/CO2 mixture used in MIG welding, TIG welding shielding gas is usually 100 percent argon. When CO2 is present, tungsten oxide is created, and tungsten oxide prematurely wears down a tungsten electrode. In addition, tungsten oxide contaminates your weld.

A foot pedal is frequently used to control the amperage while welding, albeit it is not shown in the diagram. This allows welders to fine-tune the amount of heat they apply to the metal when welding.

For further details on the TIG welding procedure, please see my GTAW welding guide.

Differences Between MIG Vs TIG Welding

As you can see from the quick description, there are substantial differences between the two ways.

What impact does this have on the weld, though?

There’s a lot more than meets the eye… Let’s take a closer look at some of the most important weld characteristics.

Stability of Welding

TIG welders produce a narrow, focused arc that successfully penetrates the metal. As a result, many welders believe TIG welds are stronger. Tack welds, for example, formed using a TIG welder, are more difficult to break.

TIG beads that have been done correctly are also clean and have a few flaws, such as holes. Weld faults weaken a weld, therefore fewer defects indicate a stronger bond.

Based on the observed penetration and the little number of visible defects, many people will believe that well-done TIG welds are stronger. That statement contains a lot of truth.

However, this may be an oversimplification. Both methods can produce strong, long-lasting welds. You can take additional efforts to boost the penetration and strength of your MIG welder.

To improve penetration, a V groove is carved or ground into the joint before welding. A good torch position and travel speed can also help you make a good MIG weld. When MIG welding is done properly, the strength often equals or exceeds that of the base metal.

Weld Speed

MIG welders are more productive than TIG welders.

TIG welding produces crisp, appealing welds, but it comes at a price. In terms of moving the weld puddle and delivering enough filler rods, TIG welders simply cannot keep up with MIG welders.

When TIG welders run for lengthy periods of time, air-cooled flames become extremely hot. As a result, a more expensive and sophisticated water-cooled torch is required.

The electrode/filler material, on the other hand, is fed automatically by a MIG welder, and its arc is rounder and wider, effectively dissipating heat.

These qualities allow a worker to move the puddle faster and run longer runs with an air-cooled flame while using a MIG welder.

For larger businesses, welding machines that can run for long periods of time and produce yard after yard of weld beads are essential.

As a result, MIG welders are commonly employed in industrial operations that require high output.

Welding Gas

A shielding gas prevents reactive gases from entering the weld puddle. Shielding gas is required for a good weld since impurities can enter the weld.

The shielding gases used in the MIG and TIG procedures, on the other hand, are not the same.

TIG welding typically employs pure argon gas. A non-reactive gas like argon is essential because reactive gases such as CO2 and oxygen are more sensitive to the tungsten electrode.

However, a mixture of argon and other gases such as helium, nitrogen, or hydrogen may be necessary for specific applications.

In contrast, MIG welders usually use a mixture of argon and carbon dioxide (e.g. 75 percent argon, 25 percent CO2). The small amount of CO2 helps to improve penetration while also keeping the arc stable.

On the other hand, the MIG gas varies according to the application. You must use 100 percent argon while MIG welding metal, for example. There’s also MIG welding using pure CO2, which is less expensive and enhances weld penetration (even though there are some disadvantages).

The flow rate is another factor to consider when using a shielding gas.

On average, a MIG weld consumes 35 to 50 cubic feet per hour. The bulk of applications will be covered by a TIG welder shielding gas flow of 15 to 25 cubic feet per hour.

Welding Aesthetics

The beads produced by a TIG welder have a clean and professional appearance. They almost never splatter, and any stains are generally only erased with a light polish (or pickling).

Many people believe that a good TIG welder’s perfectly “stacked dimes” are the standard for a visually pleasing weld. TIG welding provides an edge over MIG welding in terms of aesthetics.

When the component is not coated or painted, as is often the case with aluminum and stainless steel, TIG beads are widely used to make the finished piece more pleasing to the eye.

That isn’t to say that good MIG welding isn’t appealing. A competent welder can lay good-looking beads with a MIG welder. Furthermore, many applications do not necessitate a picture-perfect weld, and a MIG welder may be able to produce beads that meet the aesthetic criteria of the project.

Steel welds are typically coated as well. As a result, the weld’s look is less important since, as the phrase says, “paint hides many sins.” As a result, MIG welding steel with a coating is common.

Recommended Post: Best Welder For Aluminum

Welding Metals

Stainless steel

Unlike mild steel, stainless steel retains heat well. This leads stainless steel to bend at high temperatures, and it can also deform as it cools.

Welding stainless steel becomes more difficult as a result, especially for unskilled welders. TIG welders, on the other hand, have excellent heat control and can regulate the heat with a foot pedal. This means that the operator’s control has improved as a result of their previous experience.

Because of the TIG torch’s tight, focused arc, TIG welds are also tiny and precise. Because of reason, it’s an excellent choice for thin stainless steel material or fine work.

For a variety of reasons, including completed look, most stainless steel welds are done with a TIG welder.

The argon shielding gas used to TIG weld stainless steel is typically a mixture of argon, helium, and/or nitrogen. The shielding gas, on the other hand, can vary based on the stainless steel alloy being welded.

However, there are times when MIG welding stainless steel with a pulsed current is a better alternative. For example, MIG welding might be better suited to high production rates, welding out of position, or dealing with a complex joint.

Aluminum

Because aluminum is a good heat conductor, it presents a particular problem. A natural layer of aluminum oxide forms almost instantaneously when metal is exposed to air, breaking the arc. Welding aluminum is more challenging due to both of these features.

As a result, proper heat control and attention to producing a solid ground, as well as an arc capable of cutting through the aluminum oxide, are critical. The precision control given by a TIG foot pedal is important when working with a material like aluminum.

The TIG process also uses an alternating current to aid in the elimination of the aluminum oxide surface layer. This is something that only TIG welding can accomplish, and it’s one of the reasons why TIG welding is such a good choice for welding aluminum.

Like stainless steel, aluminum is commonly left uncoated. Clean, perfectly stacked “dime” TIG beads may be necessary to get the desired look.

Aluminum, on the other hand, can be MIG welded. It’s more susceptible to contamination from the environment and faults caused by little amounts of dirt or moisture. As a result, ensure that the metal has been fully cleaned and prepared, as well as that your aluminum feed wire is new, clean, and dry.

Another issue with MIG welding aluminum is that it can be difficult to feed the soft aluminum wire to the torch. As a result, some people use a spool gun to prevent wire entanglement and bird nesting.

However, if you’ve taken all of the essential precautions, a MIG welder will allow you to work with aluminum more quickly and efficiently.

Recommended Post: How To MIG Weld Aluminum

Difficulty in Learning

When TIG welding, one hand is used to handle the torch and the other is used to feed the filler rod. You can also control the amperage with a separate foot pedal while welding. You’ll need some practice to master all of these simultaneous movements.

Keep in mind that the metal must be cleaned and prepped appropriately. TIG welding generates high-quality beads when done correctly. This is an important factor to keep in mind. If you use TIG welding to save money, you’ll end up with subpar or even failed joints.

As a result of these variables, TIG welding is more complex and time-consuming to learn. Welders frequently perceive TIG welding as a more advanced, expert-level procedure.

All of this should suggest that MIG welding is easier to pick up, and it is. There are no foot pedals to worry about, and the filler material is fed automatically by the machine.

MIG welders can also be used for a variety of tasks. Workers may learn to do a wider range of jobs since MIG welders can handle thicker materials than TIG welders. All of this may also be done with just one hand.

To initiate the arc on many machines, simply pull the MIG gun trigger. MIG welders are often referred to as the “hot glue gun” of welding because of this.

When compared to the more complex TIG process, workers can quickly master the operation, increase productivity, and produce high-quality MIG welds.

Cost

Because of its sluggishness and lower deposition rates, TIG welding is more expensive per foot of bead. It also needs the employment of a more expensive expert welder.

The initial cost of a TIG welder is usually higher as well. Consumables are usually slightly more expensive than non-consumables.

A MIG welder, on the other hand, is typically less costly than a TIG welder. Furthermore, the speed advantage of MIG welding lowers the cost per foot of installed bead. Furthermore, when compared to TIG welding, less preparation work is necessary.

Because of these characteristics, MIG welds are always less expensive than TIG welds.

When Should You Use TIG And MIG Welding?

MIG-related applications

As previously stated, the MIG method has some advantages. As a result, there will be times when MIG welding is the ideal choice. Here are some scenarios in which a MIG welder would be useful:

Thicker Stock

The quick, efficient MIG process is the way to go when thicker material or larger parts need to be welded. The continuous feed wire will be more productive than the TIG hand-fed rod in terms of producing a large volume of filler material.

Long Distances

The MIG method can handle scenarios with several lengthy runs thanks to its continuously fed wire. In addition, the TIG process involves several pauses and restarts in order to purchase fresh rods or change the rod now in your hand. This raises the possibility of a weld flaw in a long bead.

Difficulty Positions

You can use the other hand to support yourself or grip components because a MIG torch only requires one hand to operate.

Production

MIG can easily install more “pounds” of weld filler and generate more feet of bead per hour than TIG. When high productivity is necessary, MIG welding is the method of choice.

Limited amount of experience

MIG welders with less experience can lay nice beads on a task using the easier-to-learn MIG process. However, they might not be able to do so with a TIG welder.

TIG-related applications

TIG welding is preferred when working with the following materials:

Thin material

Because of its precision and accuracy, TIG welding is suitable for thin materials that are prone to warping and burning through.

Experienced Welder

TIG welding is more difficult to master, but if you or your employees have the appropriate abilities, you can use TIG welds when they are the best welding method.

Nonferrous metals

When working with metals like aluminum, stainless steel, copper, and other exotic metals, TIG welding is often the first choice for professional welders. It will not, however, operate on ferrous cast iron.

Shop or Bench Work

TIG will not operate if you are out of place. When working at a bench or in a shop, though, you are rarely out of position. As a reason, TIG welding is a fantastic choice for this job.

Short Runs

TIG welding is ideal for short lengths, such as pipe joints.

Work that is delicate

When the end component must have a beautiful appearance, TIG welding is commonly used. TIG is perfect for high-visibility goods like artwork, automotive restoration, and sinks, among other things. You also have the heat control you need to avoid warping and burning with thinner, finer metals.

Conclusion

TIG and MIG are not “better” than each other. In some circumstances, depending on the variables you must manage, one may be the better option.

On steel and aluminum, MIG welding is less expensive and generates faster welds. Stainless steel can be welded, however, it isn’t the most common use for MIG welders. MIG welding is an excellent low-cost, high-volume production option.

TIG welders create precise, thin, and appealing beads with good penetration. They are, however, more costly and need the use of professional welders. The TIG process is often used for pipe joints, thinner stock, and aluminum and stainless steel work where the bead is left exposed.

TIG welding is another option for steel. MIG is a preferable alternative when the steel needs to be coated or aesthetics aren’t as critical.

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.