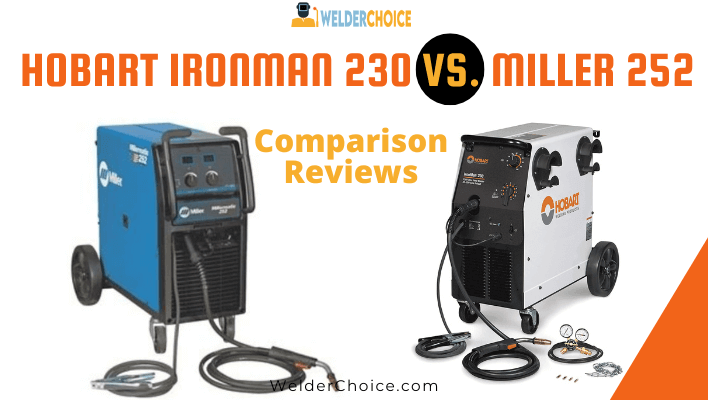

We’ll compare the Hobart Ironman 230 vs. Miller 252 in this article to find which one is best!

Miller 252 welder and Hobart Ironman 230 are made by a company renowned for producing high-quality welding equipment. You could become perplexed when aiming to select which option is the best. To help you choose the equipment that best suits your needs, we have compared the Hobart Ironman 230 and Miller 252 here.

HOBART IRONMAN 230 VS. MILLER 252

Let’s start to compare the Hobart Ironman 230 Vs. Miller 252

Hobart Ironman 230

Hobart Ironman 230 is a powerful tasking machine that professionals typically employ for minor industrial jobs. It can be used as a flux-cored welder or a MIG welder. You can set the arc for flexible handling thanks to its 12 voltage adjustment options. its weight is 185 lb.

Hobart Ironman 230 welder should only be used in industrial workshops because it requires 230 volts of input voltage to operate, not in a typical home socket. It provides amperage ranging from 30Amp to 250Amp. It offers a precise cut without extra spatter. Its drive roll application is reversible. The security of the users was taken into consideration when designing this welder. If the machine becomes too hot, a heat overload feature shuts it down immediately.

The Hobart Ironman 230 is ideal for heavy-duty jobs and professional welders. Although it has wheels, using it on a commercial site where you might need to move it frequently is not advised due to its size. It provides a thorough chart outlining how to modify a certain metal. It can weld steel and aluminum up to a thickness of 1/2 inch.

HOBART IRONMAN 230’s Pros and Cons

Pros

- It has safety features installed for your protection.

- It provides a precise performance and is easily customizable.

- Options for adjusting 12 volts

Cons

- Given that it is large machinery, it is not easily movable.

- Due to the lack of electricity in household outlets, it can only be used in industrial locations.

Miller 252 Welder

An excellent MIG welder with a focus on fabrication welder is Miller 252. This equipment is adaptable and works with a variety of wire types. It includes a rolling cart, so it is quite portable. The needed input voltage is 230 volts, which results in a 30 amp to 300 amp amperage range and a 50 IPM to 700 IPM wire feed velocity range. It carries about 205 lbs.

It includes a 15-foot gun cable and a 10-foot power cord. It features an integrated consumable storage box, a welding parameter graph, and touch-sensitive settings adjustment. This equipment also has a recall application that enables you to work continuously without constantly readjusting the equipment’s voltage.

The Miller 253 welder is an appropriate piece of machinery for auto part repair welding, metal sculpture workshops, ranch welding projects, etc. since it can weld normal steel, stainless steel, and aluminum. Because it has an automatic gun detection feature and a double gear drive application, it is appropriate for some experts who must constantly work throughout the day on welding works that are identical to one another or on a big welding project. The user may easily complete their assignment thanks to this feature, which saves them time and effort.

MILLER 252’s Pros and Cons

Pros

- Your work is made easier by Miller 252’s automatic gun detecting features.

- It has a convenient flip-down compartment.

- You may operate on larger metal units without having to move the equipment because the gun range is 15 feet.

Cons

- It is heavy, weighing 205 lbs.

- Expert welders should use this equipment instead than beginning welders.

Key Difference between the Hobart Ironman 230 and the Miller 252

Although both of these machines are excellent for welding tasks, significant distinctions make one more effective than the other. Following is a comparison between the Hobart Ironman 230 and the Miller Electric 252.

Hobart weighs 185 pounds compared to Miller’s 205 pounds, although it is believed that Miller is more easily portable than Hobart because it comes with a solid rolling cart while Hobart has wheels.

The required voltage for Hobart is 230 volts, with an amperage range of 30 to 250 amps. The 230 volts and 30 amp to 300 amp amperage ranges are needed for Miller.

Miller’s duty cycle at 200A is 60%, so if you’re welding at that current, you can continue doing so for 6 minutes before stopping. Hobart operates at a duty cycle of 60% at 170A. In order to let the machine cool down, Hobart allows you to weld for 6 minutes at 170A before you finish or stop.

Final Thoughts & Recommendations

Since you select the equipment based on the kinds of projects you will be working on, it is impossible to determine clearly which system is superior in this comparison. We have included the characteristics, benefits, and drawbacks of both pieces of equipment along with the distinctions between the Hobart Ironman 230 and Miller 252 welder.

Miller has numerous extra features that are unnecessary for a novice welder or hobbyist, and they may find them confusing and challenging to control. Despite having many features, Hobart Ironman 230 is comparatively more comfortable to use. Miller, however, is the best option if you need to complete large jobs.

FAQs

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.