Do you have a hard time understanding what plasma cutting entails? When you first look at it, it may appear to be a very difficult field to work in.

Even the terminology might be perplexing; what exactly is a “swirl ring” while you’re at home, for example?

Fortunately, scratching beyond the surface reveals that it isn’t quite as complicated as it appears. Plasma cutting is rather straightforward in practice, despite the fascinating science and incredible output temperatures.

As a result, we’ve created a comprehensive guide to plasma cutting that will teach you everything you need to know. It starts with “what is plasma?” and progresses through the fundamentals. After that, he walks you through the ins and outs of plasma cutting before answering some of the most often asked questions about it.

We guarantee that by the end, you’ll understand everything and be able to explain plasma cutting like a pro.

What Is Plasma?

Before we can understand how plasma cutting works, we must first answer the question, “What is plasma?”

You may recall learning about the three states of matter in school: solid, liquid, and gas. Plasma is the fourth state of matter, and it exists in addition to the first three.

When you add energy to a substance’s molecules or atoms, it transforms from one state to another. When ice is heated, for example, it melts and becomes water.

If you heat it for a little longer, it will change into a gas, or steam, which we call water vapour. Finally, if you heat it, even more, the gas separates into ions, at which point it becomes a plasma, which may conduct electricity.

What Is A Plasma Cutter And How Does It Work?

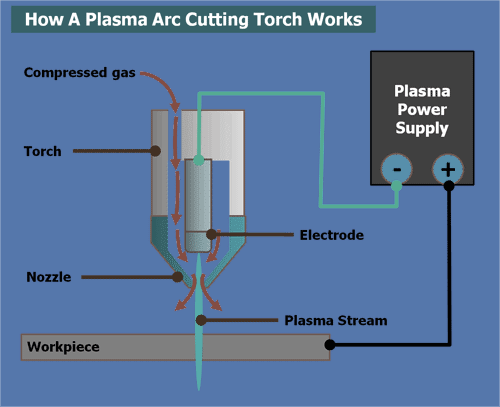

To put it another way, plasma cutters drive an electric pilot arc through a small gas-filled opening. Any plasma gas, such as oxygen, argon, shop air, nitrogen, and so on, can be employed.

The temperature of the gas is raised to the point that it can transition into plasma, the fourth state of matter, as a result of this process.

Because plasma is a conductor of electricity, it can form a circuit with the metal (or other material) being cut, allowing the plasma arc to cut through it.

A nozzle is a narrow aperture with a small opening. The gas is forced through the tight orifice at a high rate and the high-temperature gas that travels through the nozzle onto metal slices through the metal like a knife slices through butter.

In most high-quality plasma cutters, the pilot arc acts between the electrode and the nozzle to ionize the gas before the arc transfer.

In lower varieties of the plasma cutter, the plasma generation may begin when the torch tip is used to force a spark by being touched to the metal surface, or it may use a beginning circuit (a high-frequency design that is very much like a spark plug in a car engine). It’s worth noting that CNC cutting machines can only be used with a pilot arc plasma cutter.

Handheld Operation

After using a handheld plasma system (110v/220v plasma cutting equipment), keep in mind that when the system is shut off, the nozzle and electrode will be touching within the torch.

When you push the trigger, the connection receives a DC current from the power supply, and the plasma gas begins to flow at the same time.

Inside the nozzle, the plasma gas builds up pressure until it is strong enough to detach the nozzle from the electrode. The pilot arc is created, which allows the gas to transform into a plasma jet.

As soon as the DC current flow moves from the electrode to the nozzle, a path is formed between the electrode and the workpiece being cut. This will remain in place until the trigger is released, after which it will revert to the OFF state.

Precision Plasma Operation

In a precise plasma torch, things are different. The electrode and nozzle are separated by a swirl ring. This is a ring that drives plasma gas preflow into a vortex and has tiny venting holes.

When the power source is turned on, it generates a 400-volt DC open-circuit voltage. This turns on the plasma gas flow into the torch. At this stage, the nozzle connects to the positive potential of the power source, establishing a pilot arc circuit. The electrode is, of course, pushed to a negative potential at this point. After that, the Arc Starting Console fires a high-frequency spark (again, similar to a spark plug).

As a result of this spark, the plasma gas is ionized and gains the ability to conduct electricity, resulting in a full pilot arc. As soon as the arc makes contact with the workpiece, the current shifts to link the electrode to the metal being cut. As you operate, the workpiece is constantly sitting on a fully grounded cutting table, preventing the energy from travelling elsewhere.

This modifies the DC current to create the correct amperage as defined by the plasma cutter’s user, as well as switching out the preflow of gas to the ideal blend of gas for the material you’re cutting. The plasma arc is then further focused by supplying shielding gas through the nozzle, allowing for a very clean cut with the smallest possible bevel angles and kerf.

The Plasma System’s Components

There are five basic components that make up the plasma system:

The Power Supply

The power supply transforms single-phase or three-phase AC line voltage into 400 VDC useable DC voltages. As a result, the plasma arc will remain stable throughout the arc cutting procedure.

Arc Starting Console

The Arc Starting Console is a basic circuit that delivers an AC voltage of around 5,000 VAC at 2MHZ to produce the spark that starts the plasma arc (a very high frequency).

Gas

Gas flow is essential and plasma systems can use nearly any gas, but nitrogen, shop air, oxygen, argon, and other gases are the most prevalent.

These can be used for two different purposes:

- To construct the plasma arc’s base for a better cutting experience

- To protect the plasma for a better cutting experience by forming the plasma arc’s base.

Cooling

Plasma cutters get so hot that the nozzle or electrode would catch fire if they didn’t have a cooling system. A liquid cooling system is used to keep the temperature under control at all times.

Torch

The plasma torch is used to ensure that the plasma arc is properly aligned and that the cooling system is functioning properly. A plasma cutter’s consumables include nozzles, electrodes, and swirl rings.

Material Considerations

Only electrically conductive things can be cut using a plasma cutter. Because the substance is a component of the plasma arc’s circuit, this is the case. If it is not electrically conductive, there is no circuit and no cutting.

As a result, it works well with a variety of metals, including:

- All types of steel are accessible, including stainless steel, structural steel, non-alloy, high-alloy, and low-alloy steel.

- Aluminum

- Clad metal plates

Plasma cutting is also possible with brass, cast iron, copper, and titanium, however, the melting temperatures of these materials make producing a sharp cutting edge challenging.

Plasma cutters can cut through materials with thicknesses ranging from 0.5 mm to 180 mm, depending on the plasma cutting equipment and the substance.

The Plasma Arc Cutting Process

Although there are several modifications to the plasma arc cutting process, the core principles remain the same whether you’re cutting stainless steel, structural steel, alloy steel, copper, or any other material or sheet metal.

This procedure is divided into five stages:

Initiation

Pilot Arc Initiation – this is when the start instruction is given and the initial arc is produced to start the gas intake to the electrode and force it out through the gas nozzle.

Main Arc Generation

The next step is to ignite the arc and ensure that an electric arc forms between the electrode of the plasma cutting machine and the workpiece. Cutting can begin at this stage, and if two plasma gases are required, the shield gas will start to flow to hone the cutting flame.

Local heating

Localized Heating and Melting – As the plasma warms up, the temperature rises, causing localized heating and melting of the workpiece. However, this can also cause problems within the nozzle, necessitating the use of a cooling system.

Material ejection

Material Ejection – The plasma jet gas flow’s kinetic energy is employed to expel the weaker material from the workpiece from the kerf.

Movement

After the material is ejected, the plasma arc is pushed across the surface of the material until the cutting process is complete.

Variants Of The Plasma Arc Cutting

In general, the plasma cutting procedure is the same regardless of the version. Each cutting variation, however, offers a specific benefit based on the application.

The variances are believed to be unique ways of using cutting plasma depending on the cooling system, the electrode design in the plasma torch, the plasma jet gas used, or the ultimate type of cutting plasma released.

Some of the possibilities are as follows:

Standard

Standard/Traditional Plasma Arc Cutting – the nozzle aperture is the only thing utilized to constrict the plasma arc, and no additional medium is required (the coolant is typically water or air).

With secondary medium

Plasma Arc Cutting with a Secondary Medium – A secondary medium (another medium) is drawn into the plasma torch to confine the plasma arc and provide particular properties based on the plasma jet’s intended application.

With water injection

a water injection Water is fed into the plasma arc in this type of plasma arc cutting, boosting the temperature to above 30,000 degrees centigrade via the gas nozzle, which can improve the cut quality.

Advantages And Disadvantages Of Plasma Cutting

Advantages

- Depending on the series of plasma cutting machine, one or more burners can normally be used at the same time.

- Any electrically conducting substance can be sliced through.

- Medium and large thicknesses of high-alloy steel, aluminium, and comparable materials can be easily hurled.

- Mild steel at small and medium thicknesses performs admirably.

- It is feasible to cut high-strength structural steel without cutting as much heat as other cutting methods.

- Plasma cutting speeds are around ten times faster than oxy-fuel cutting speeds.

- It allows you to efficiently process a high-quality blank for thick and medium sheet metals.

- Plasma arc cutting is ideal for automating cutting processes.

- The noise level is very low and the heat exposure is also very low while plasma arc cutting underwater.

Disadvantages

- When working with dry plasma arc cutting, the maximum cut size is still 180 mm, and when working underwater, it’s just 120 mm.

- Despite this, the kerf is a little wider than ideal.

- Plasma arc cutting consumes a lot of electricity.

- It costs more to run than an oxyacetylene system

- It does not produce the same high-quality cuts as laser cutting.

- You may have noticed that dry cutting produces more noise than you would like.

FAQs

Is the Fume from Plasma Cutting Harmful?

Plasma cutting gases are not technically dangerous, but the vapours from the sliced metal are. When most metals are burnt in the air, toxic deposits form that should not be inhaled; even iron oxide (rust) can accumulate in your lungs and cause major health problems if inhaled over time.

Is it necessary to use a welding mask for plasma cutting?

Officially? No. You could get away with just wearing safety goggles for plasma arc cutting, but we recommend wearing both safety goggles and a welding mask for essential plasma cutting. Regardless of the cutting process, this gives the best protection for your eyes.

Is it possible to use a plasma cutter to cut wood?

How does plasma cutting operate and what is it used for? It is the use of plasma arc cutting to cut materials, and the material being cut must be electrically conductive in order for this to operate. If the material isn’t electrically conductive, the arc will fail; wood isn’t electrically conductive, so a plasma cutter won’t be able to cut it.

Is it feasible to use a plasma cutter to cut rusty metal?

Rust has no effect on the plasma arc cutting process because it conducts electricity exactly like any other metal. With the same precision as stainless steel, it can cut filthy steel, corroded steel, and even painted steel.

Is Using Plasma Cutters Safe?

Yes. Plasma arc cutting produces a great deal of heat. Your eyes (you should always wear side shielded glasses and a welding helmet), your clothing (fire-resistant clothing is required), and even your feet and hands are at risk (special gloves and shoes are required).

Despite this, sparks or molten metal can cause fires in the workplace or on the cutting table.

What Does the Future Hold for Plasma Cutting?

High-end plasma cutters can now cut through 200 inches of a metal plate in less than a minute. In the process, they generate 40,000 degrees of heat.

That’s a non-issue. Scientists have recently shown the ability to make a cutting plasma with a temperature of up to 10 trillion degrees. Of course, a cutting plasma instrument like this would almost definitely never be used to cut through metal, but it does show that this technology has a lot of potential in the future.

The plasma cutter’s current problem is the waste it produces, notably dross. This is a type of molten metal residue that sticks to the metal’s corners and drastically decreases cut quality.

On the other hand, the cut quality of laser or water cutting technology is significantly superior to that of plasma cutting. That means that after the cutting is finished, no further effort is required.

“What is plasma cutting?” you might wonder. Some workshops can be questioned. They’d say it’s a generator for finishing work. They’d prefer to use laser or water cutting equipment in their firm, but these machines are more expensive, rarely portable, and take up to 100 times longer to finish than a plasma cutter.

As a result, plasma cutting’s hoped-for future is a smoother sliced finish. They will be an unstoppable force in the cutting industry if they can do this while keeping plasma cutting at its current speed.