Here we can know about “How To Clean Welding Helmet Lens?” I’ll just start by saying that you shouldn’t bother cleaning and restoring lenses if you have a cheap helmet and your employer provides all of your welding equipment. In this situation, replacing them is the smartest move. Therefore, dispose of the old shielding lenses and buy new ones.

On the other hand, you should read this article if you are the proud owner of a $300 or more Optrel or Esab welding helmet with those pricey clear welding lenses.

For a, let’s face it, cheap piece of plastic, those lenses are too pricey (especially if you are a type of welder that sticks his head when welding with MIG or flux core). These are a few of the greatest techniques to clean and restore them, so you should try to do so.

How To Clean Welding Helmet Lens

What Leads To The Lens Getting Dirty?

- Dust, Dirt, and Grime: if you are a TIG welder welding some stainless steel in a shop, kitchen, or power plant. The rest of us are at home in a filthy, dusty workplace. Particularly if you occasionally use a grinder in between welding sessions, dust will soon build up on the welding helmet lens. Throughout your working hours, you will need to wipe it off numerous times.

- Welding Smoke: Most electrodes used for MIG and Stick welding emit weld smoke, which will quickly build up on your welding helmet if you bury your head in the welding fumes.

- Weld Splatter: The weld splatter is the most harmful to the lens of your welding helmet. Sometimes you can’t stop it by just moving away, especially if you are welding in a confined place or on a dirty object. The helmet will sustain long-term damage from hot metal spray sticking to it (Tho in some cases, the lens can be brushed and restored)

- Scratches: Welders frequently place their helmets face down, especially if it’s not their own, scratching the lens in the process. You may anticipate that when you take up your welding helmet, there will be a scratch on the lens. When you weld, surface scratches won’t be visible as long as there aren’t many of them, and in some situations, they can be buffed and brushed out. But until you replace the welding helmet lance, you’ll probably have to put up with the deeper scratches.

How To Clean The Lens Of Your Welding Helmet

However, the first thing that springs to mind is that you should never use a wet tissue, soft cloth, or any other material to clean the grimy lenses of a welding helmet. Why? Well, there’s probably some hot metal splatter or grinding wheel dust sticking to it.

Second, pulling those metal flakes when you rub the cover lens with a soft cloth or any other material would harm the welding lens more severely.

1. Clean the lens of your welding helmet with water

Due to lack of time or laziness, most welders choose not to remove the cover lens and position it under the water stream, but this is the wisest course of action. Water can be room temperature, hot, or cold; it makes no difference.

Any potential dust and spatter particles will be eliminated by the water. Once the water and remaining dirt have been removed from the cover lens, you can carefully clean the lens with a microfiber cloth or another soft cloth.

The protected lens will still have some minor scratches, but that is not the goal. The objective is to clean the dust and dirt from the welding gases.

2. Finish the cleaning with high-quality auto wax or furniture polish

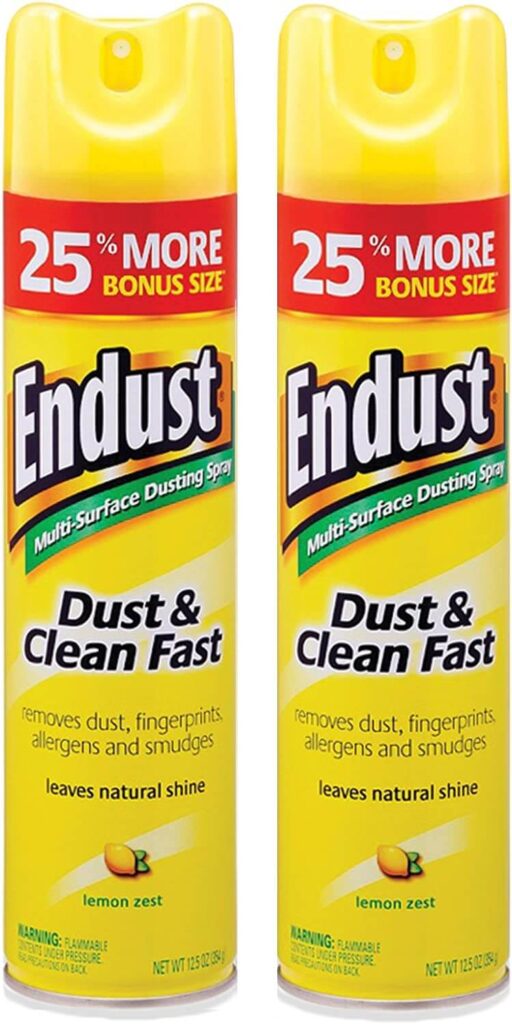

If you have the time, finishing the cleaning with a polishing agent is also a good idea. These cans are pretty inexpensive and leave the welding hood with a wax coating that functions as a form of multi-layered lens protection.

This coating will make it more difficult for hot metal spatter to adhere, and because it makes your clear lens more slippery, fingers would leave fewer marks on a lens. The easiest technique to get a clean welding helmet will require some of your time at work, but it can be done.

There is a specialized lens solution that will speed up this procedure if the cover lens is very dirty, but I would stick with water and wax or, in the worst situations, dish detergent.

3. Cleaning the filters for automatic darkness

Well, I don’t suggest cleaning the auto-darkening filters themselves. Simply keeping your fingers away from the auto-darkening filters on the welding helmet is a smart idea, especially if you’re wearing grimy welding gloves. But suppose the ADF filters did get soiled in some way.

If so, there are no special cleaning techniques to apply; instead, follow the instructions in the helmet’s user handbook. Still, as I’ve said in most situations, you should merely use a microfiber towel or a brush with soft bristles to delicately clean the ADF’s delicate surface layer.

It goes without saying that you must avoid using water for this step, rinsing the front of the ADF filter, or using anything that could scratch or harm the lenses’ surface.

4. Cleaning a welding hood’s interior

As you are aware, welding involves a lot of heat and perspiration. The headband and headgear need to be cleaned frequently since they are covered with sweat and are a breeding ground for bacteria. Welders hats can help with this, but you should at the very least wash the front headband every day after work.

Additionally, this is the main justification for not using someone else’s welding helmet. Additionally, cleaning the interior of the helmet is a good idea because you practically wear it on your face for several hours every day.

Finally, exercise caution when using welding helmets powered by batteries near the battery region. It’s preferable to remove them all at once while cleaning because you might easily harm the circuits and sockets that house the battery or any other concealed components.

One additional thing to keep in mind when cleaning the inside of the welding helmet: the protective lens inside is considerably more delicate than the one outside. Even the softest fabric will leave a trace on it, so be careful when cleaning it to only use water and avoid any form of scrape.

How Can a Welding Helmet Lens Be Restored?

1. Use a soft buffing wheel and polishing belt.

What should you do if cleaning your pricey welding helmet’s clear lenses doesn’t work and they are covered in metal splatter and scratch marks?

Don’t discard it! more so if you possess a polishing machine.

All you need is a polishing belt and soft buffing wheel for your grinding stand, though an angle grinder with a mild buffing compound attachment will also work beautifully.

Move the dusty lens up and down while lightly pressing it against the polishing wheel. With this method of cleaning your welding, you may get rid of scuffs, dirt, and other foreign objects. After doing the same with the polishing belt, you’ll have a clean welding helmet and savings of up to $10 on a new replaceable clear lens.

2. Polycarbonate-safe rubbing compound (your lens is made of it)

Your front cover can also be restored with this one if you don’t have a grinder or a shop. Finally, after wet sanding your car, car dealers and auto shops will polish it using this rubbing compound. Both welding helmet lenses and automobile headlights will work well with them.

The cost of this rubbing compound is a drawback, but if you plan to work in the welding industry for a while and have an expensive welding helmet, it will pay for itself given that you only need to use a few drops per cleaning.

Simply apply a few drops to the lenses of your welding helmet and massage with a microfiber cloth until all soft scratch marks and other debris are gone. If necessary, repeat this process several times to achieve the best results and save money on new lenses.

Tips For Maintaining Clean Lenses

- As much as you can, keep your head clear of the welding fumes. If necessary, use a magnifying lens.

- In addition to the basic health risks that welding gases provide and the necessity to protect your respiratory system, the welding helmet will quickly become full of dust and fume residue.

- Use an inexpensive polish product to finish cleaning your lens after routine cleaning. It helps increase productivity, saves money, and somewhat extends the lens’s useful life.

- Never ever leave your helmet on its face, especially at work. The front shield lens will become scratched and cracked, and dust will accumulate inside the exposed areas. Use a bag to safely store your helmet for this.

- To extend the life of the welding helmet’s batteries, remove them when not in use for longer than a week. To extend the life of the solar cells in a welding helmet, store it in a dark area after work. A bag or welding helmet backpack should be used to store the hood.

- Every day after work, wash and sterilize the front and back swat bands. If you don’t, it will clog up with bacteria, sweat, and filth, and your forehead pimples will be your last concern.

Cleaning auto-darkening hood vs. Passive welding helmet.

Most field welders use the basic pancake passive hoods primarily for cleaning purposes. Modern helmets are a weight on you in the mud, sand, and generally in the outside weather conditions.

In these circumstances, it is difficult to maintain the ADF filter lenses and the rest of the fine technology clean, and the lifespan of the helmet is significantly reduced due to the continual wear and tear required for tasks like pipe welding. The front lens is inexpensive and removable, so there is no need to spend time away from your business to clean it for these straightforward helmets, which can be maintained with simply a clean rug.

Therefore, avoid cleaning and maintaining ADF hoods if you plan to conduct fieldwork in poor weather. Simply purchase and wear a cheap passive helmet. With a bit less clarity, it will provide the same protection.