Any professional welder should be able to handle pipe beveling, but that doesn’t mean a DIYer can’t attempt it as well. If you want to weld two pieces of pipe together, your pipe must be beveled. When joining pipes, beveling is essential, but there are a lot of other things to consider and learn about to ensure the best weld union.

Everything you might possibly need to know will be covered in this essay about how to bevel a pipe for welding.

What is Pipe Beveling?

Pipe beveling is the process of forming an angle between the pipe and the surface on which it will be welded. Beveling aims to neaten and smoothen the tube ends for safety. All welding techniques’ aesthetics are also enhanced by it.

To put it simply, pipe beveling is the process of changing the geometry of pipes before they are welded to enhance fit. There are various methods to bevel pipes, whether using a machine or a hand grinder.

Why Bevel a Pipe?

The main purpose of beveling a pipe is to prepare the pipe’s end for welding. If the surface is sufficiently smooth, the shape can be easily connected to it. Deburring the ends of cuts is another aesthetic and safety benefit of beveling a pipe.

Is Chamfering The Same?

To make a symmetrical slope edge in carpentry, chamfering involves cutting a corner or right-angled edge. Like beveling, chamfering aims to simplify assembly and get rid of sharp edges to reduce the danger of injury.

Despite the fact that the terms chamfering and beveling are frequently used interchangeably, they are not the same. Chamfering is a form of beveling, however, a chamfer is an edge that meets two surfaces at a 45-degree angle rather than a bevel, which can slope at any angle other than 45 or 90 degrees.

Pipe Beveling Methods

There are numerous ways to bevel a pipe, depending on your tastes. After being beveled as a kind of preparation, the pipe can be welded. You can either use a hand grinder, a plasma cutter, a portable or stationary beveling machine, or perhaps both.

Hand Grinding

Hand grinding is the simplest and least expensive way to bevel a pipe, but this does not make it straightforward. The process would require a lot of time and expertise. Additionally, utilizing a hand grinder prevents you from producing different bevels.

If you use a hand grinder, you’ll create a lot of mess and run the danger of injury. When the pipe is eventually brought to the top and gathered, irregularities caused by hand grinders could potentially lead to a poor weld.

If you still decide to use a hand grinder to weld your pipe, you can follow the directions in the manual that comes with it once you purchase it.

Torch/Plasma Cutter

Another tool you can use to bevel a pipe is a torch cutter or plasma cutter, however, because you have to cut the angle with your hand, this method is similar to using a manual grinder. To conserve space and allow you to guide the flame, use the cutter with a clamp-on machine.

For swiftly beveling your pipe, a plasma or flame cutter might be more effective than a hand grinder. Your work may be exceedingly disorganized and contain errors if you lack equipment proficiency. Additionally, the machine generates a fire risk, making it impossible to make J bevels or all materials with it.

The flat surface at the end of the pipe must also be securely prepared using your hands, which is riskier than doing it with a skilled plasma cutter.

Portable Beveling Machine

Beveling a pipe is made easier by portable beveling equipment. Due to their numerous features and configurations, these machines are far more straightforward and secure than the first two methods mentioned above.

The tools are easy to use and portable. In comparison to the previous way, they would also offer much more consistent levels and save a lot of time. Flying chips from the pipe could pose a risk to the machine and the electrical cables. These goods could also be expensive, especially if they come with extra features.

Stationary Beveling Machine

The last way of beveling a pipe involves the use of a stationary beveling machine, which would meet most of the requirements for expert beveling. The device is used to manufacture any form of bevel and has a high output.

Stationary beveling machines, which use reasonably priced carbide cutting inserts, are easily incorporated into automated production lines. Any sort of bevel, including J-bevels, can be produced by the machine, which doesn’t need to be supervised. The machine doesn’t rotate after the pipe is entered, and it has a drawer that collects all the metal shavings, so you don’t have to worry about making a mess.

Although the fixed machine costs more, it runs more quickly. It also leaves no mess, is safe, and needs no maintenance. With the machine, which is easy to set up, many kinds of bevels, pipes, and tubes can be used.

Beveling Techniques

There are different ways to consider in addition to the various pipe beveling procedures. The most popular beveling technique is a 37.5-degree bevel measure in the direction of the pipe face. Other types of beveling techniques include the V bevel, X bevel, J bevel, and U-bevel single.

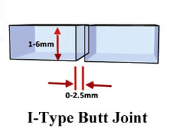

I-Type Joint Butt

The I-Type joint butt appears in first on the list even though it’s not quite a beveling joint. The agreement specifies that two popes should be connected in parallel. This junction can occasionally be mistaken for beveled joints because it is not required to be made at a precise angle.

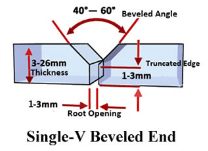

V-Bevel

The most fundamental beveling method is the V bevel. To create this angle, metal is removed at a 45° angle from the top to the bottom edge. The V shape created when the pieces are beveled together suggests the name of the design.

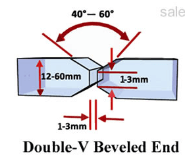

X-Bevel

Another beveling technique is the X bevel, which is comparable to the V bevel but has a stronger connection. An X bevel necessitates the removal of material from both sides, in contrast to a V bevel, which only requires the removal of material from one side of the pipe. A solid joint is produced by obtaining a V-shaped angle that is half as steep.

J-Bevel

J bevels are just as common as V bevels, but because they are harder to make, neither a hand grinder nor a torch or plasma cutter can make them. A J bevel doesn’t need to be cut from top to bottom as a V bevel does. In addition, a little section of the metal in the weld area is not beveled, suggesting that the bevel is not straight.

As implied by the name, the design is roughly shaped like a J and has a slight downward slope. The J bevel produces an equal bonding layer and takes less material to fill than a V bevel. It is challenging to make, but it has many benefits for you.

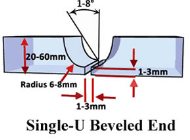

Single U-Bevel

The Single U-bevel has the strongest joint and uses less material than the V bevel despite being the most expensive to build. However, because of their radian shape, welding is more challenging.

When creating bevel joints, there are a few technical considerations that must be made. As a result, you must decide which methodology and method to use.

How Do You Pick the Right One for You?

The optimal beveling technique should be chosen after considering a variety of factors. These include the degree of technical proficiency required to operate the machinery.

- What is the bare minimum that the pipe you want to build must meet?

- How much time is required to create each bevel?

- Are you in need of a portable device?

- Does the machine have to move toward the pipe or tube, or the other way around?

- What specifications do you require?

- Does your beveling machine need electricity to operate?

Final Thoughts

Beveling becomes easier with repeated practice and as long as you’re using the right tool. It is usually preferable to utilize a fixed beveling machine rather than another kind because of its many benefits. It is time and money efficient and requires minimal ability. It is safe to use and may be used with a variety of tools and materials.

After carefully evaluating your project’s options, select the best solutions, and start beveling your pipes before welding.

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.