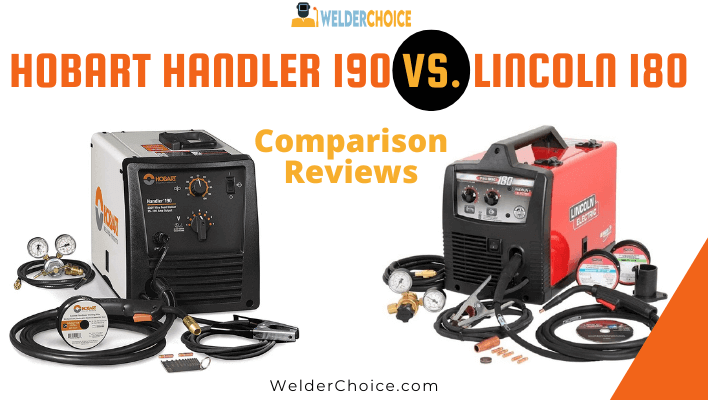

We’ll compare the Hobart Handler 190 Vs. Lincoln 180 in this article to find which performs better.

The designers of the Lincoln 180 and Hobart Handler 190 are renowned for producing high-quality, user-friendly machinery. Both types of machines come with appealing and user-friendly features that draw in customers. While trying to decide which is the greatest choice, you could become confused.

So that you may choose the equipment that best suits your needs, we have provided individual reviews and a comparison of the Hobart Handler 190 vs. Lincoln 180 below.

What is in Hobart Handler 190?

The Hobart Handler 190 is a practical piece of welding equipment. Such robust equipment can simply be employed in residential outlets because it can operate with 230 volts of power. You can handle a variety of materials extremely quickly because of the machine’s 25 Amps to 190 Amps amperage range.

It features precise arc execution, wire velocity control, improved magnetism to raise the construction level, and seven adjustable voltage options. It works well for welding material that is 5/16 inches thick. All of the extra characteristics enable it to weld with less spatter and sparks. It comes with a five-year warranty.

When Should Hobart Handler 190 Use?

The Hobart Handler 190 is a sturdy and adaptable piece of equipment that can weld aluminum and steel (including flux-cored steel, mild steel, and standard stainless steel). Because of its appealing qualities and durability, most people favor this equipment. This welding equipment was created with novices in mind; it is portable and has a small footprint. It can easily operate in secluded areas.

Even if the thickness range it offers is lavish, it is primarily utilized for DIY projects at home rather than for heavy-duty industrial work. It can be used for light welding tasks, garage maintenance, and medium-level construction tasks at ranches and farms.

Pros & Cons of Hobart Handler 190

Pros

The Hobart Handler 190 is a reliable machine that can operate on both produced and manual materials.

The voltage range, amperage range, and spool gun velocity level may all be simply adjusted to meet your demands.

This machine features an easy installation method, making it manageable for any novice welder. For better comprehension, a thorough instruction manual is included.

It has a built-in contractor and protects against short circuits.

Cons

Heavy industrial projects shouldn’t use it. Home DIY projects are the main usage for it.

This welding machine’s cord is far too short.

What Is In Lincoln 180?

The excellent Lincoln 180 welder boasts a motor that runs quietly. It includes specialized wires and spool guns, which are highly useful for welding tasks. It has five voltage adjustment choices, requires 208 or 220 volts of input power, and has an amperage range of 30 to 180 amps. A three-year warranty is provided.

It has automated shielding technology installed. When it comes to cutting metals, the ARC performs really well. The spool gun’s wire drive is fully adjustable, and the way the wires are handled is organized in a way that keeps them from tangling.

When Should Lincoln 180 Use?

The Lincoln 180 is capable of MIG and flux-cored welding. Consider buying a Lincoln 180 if you are a beginner or enthusiast. While there is no denying that this machine is quite adaptable, its weight may provide a challenge if your project calls for you to move about a lot.

You can weld without gas with this device. You are able to work for lengthy periods of time without frequently overheating continually thanks to the configurable control choices and other notable characteristics.

Pros and Cons of Lincoln 180

Pros

- Lincoln 180’s dual voltage capability enables welders to comfortably work with various types of metals.

- Its characteristics keep the device from breaking down from overheating and keep it operating effectively for a long period.

- This large machine can operate with both thick and thin metal sheets and has an automatic wire shielding mechanism.

Cons

- It has a meager amp count and power output.

- When compared to other items, the warranty duration is also shorter.

- For moving the machine to various locations, you might need to purchase a cart.

Significant Difference between the Hobart Handler 190 and the Lincoln 180 Welder

Both are great for welding jobs, however, due to a few differences, one is superior. Following is a comparison between the Hobart Handler 190 and the Lincoln 180

- While Lincoln 180 offers both a flux-cored and MIG welder, Hobart Handler 190 only offers a MIG welding machine. This attests to the Lincoln 180’s adaptability.

- Lincoln 180’s diamond core system, which also eliminates congestion while regulating the current course, gives it greater stability than Hobart.

- Hobart Handler 190 has a duty cycle of 30% at 130 Amp while Lincoln 180 has a duty cycle of 30% at 130 Amp.

Final Thoughts

Since you select the equipment based on the kind of project you will be working on, it is impossible to say definitively which system is best in this comparison of the Hobart Handler 190 and Lincoln 180. Lincoln 180 is the best option because it can operate smoothly at a low voltage, making it perfect for any DIY or small maintenance you want to conduct in your garage.

Hobart Handler 190 is a competent option if you are performing a professional industrial job because it is sturdy and provides a variety of power.

FAQs

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.