Custom welding helmets are not difficult to DIY if you think it’s difficult so here we listed some best Custom welding helmets.

Most helmets on the market are designed to be cool, which is appropriate considering the nature of the welding work. Helmets come in either plain black or color with an industrial feel.

While you’re reading this, I think you don’t like it. Some of us have a creative mind and prefer expressing ourselves through our gear, and what better way to do so than with a fashionable helmet?

I’ll show you a few of the most interesting cool and best welding helmets in this article, but these helmets have a lot more to offer than simply their looks. What good is a gorgeous helmet if it can’t do its job properly?

All of the helmets in this review meet the ANSI Z87.1 – 2003 (also known as ANSI Z87+) standards, ensuring that lenses and helmets have undergone independent testing and can withstand high-velocity impact.

Best Custom Welding Helmets for money – Reviews

Here we review the best custom welding helmet.

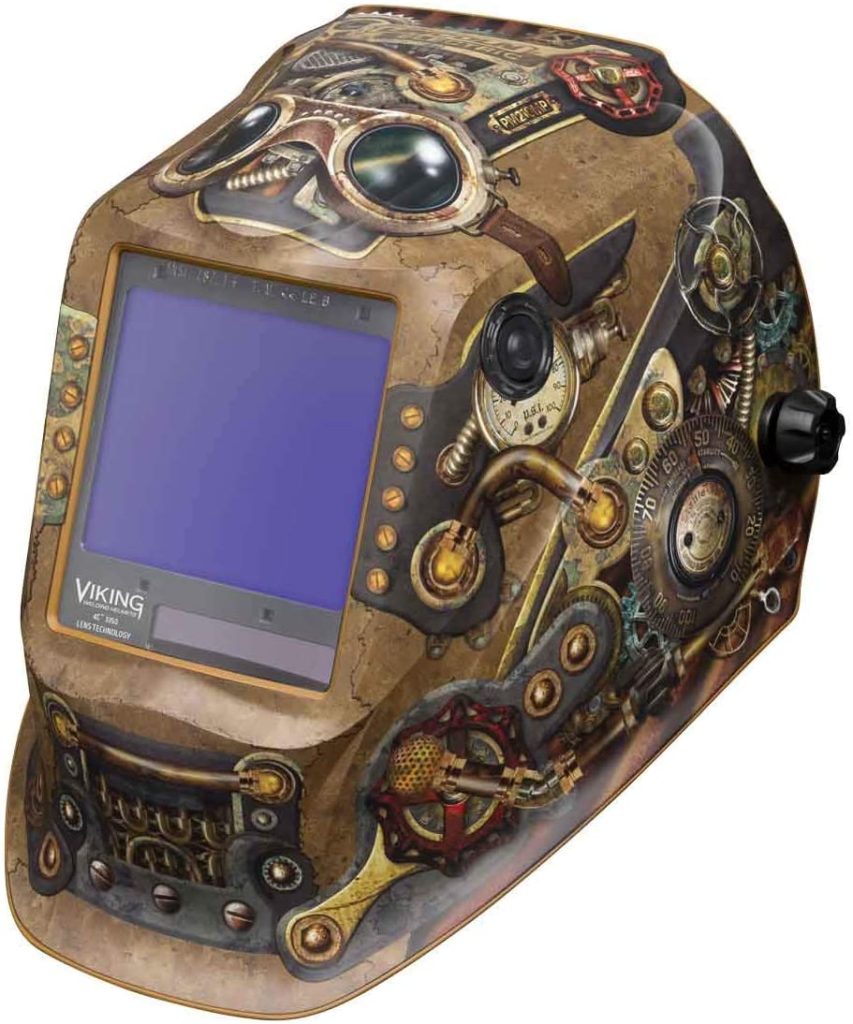

1. Lincoln Electric VIKING 3350 Steampunk Welding Helmet

2. ArcOne 5000V-1171 Python Welding Helmet

3. Instapark ADF Series GX990T Auto Darkening Welding Helmet

4. Jackson Safety Insight Variable Auto Darkening Welding Helmet

5. DEKOPRO Solar Powered Welding Helmet – Blue Eagle Design

6. Antra AH6-260-0000 Auto Darkening Most Popular Welding Helmets

1. Lincoln Electric VIKING 3350 Steampunk Welding Helmet

- 4C Lens Technology improves visibility and reduces eye strain

- Better clarity, real color view – 1/1/1/1 Optical Clarity

- Easy on the eyes

- Wide-screen view

This beautiful Steampunk adaptation is one of the top ten helmets today. The Lincoln Electric VIKING 3350 welding helmet has the clearest optics and the largest viewing area in its class (3.74 in 3.34 in (95 mm x 85 mm). Lincoln is the best brand for helmets.

It can also be used magnified with the “CHEATER” enabled lens. The shading’s opacity goes from 5 to 13. Low-amperage welding, as well as Oxy-fuel welding and Plasma cutting, necessitate an extremely low shading level. It has four sensors and is powered by a combination of solar cells and a replaceable battery.

The improved headgear is made to be more comfortable and better fitting. The 4C Lens Technology increases visibility and lowers eye strain by using a wide-screen. If welding fumes are blowing your way, there is enough room in the Lincoln Electric VIKING for a respirator, which you should use. In temperatures ranging from -10°C to +55°C (14°F to 131°F), the face visor can be worn.

Pros

- 4C Lens Technology.

- The extra-large view.

- Comfortable.

Cons

- The grinding button is inside.

- Expensive.

2. ArcOne 5000V-1171 Python Welding Helmet

- solar powered, no need to replace batteries.

- whole head, neck, and ear protection

- Polycarbonate is being used to replace the front-loaded polycarbonate.

- Ratchet headgear with Perma-lok locks into place

ArcOne 5000V-1171 Python Custom welding helmet with a big grin and some decent features. Because it is solar-powered, there are no batteries necessary for this fantastic welding minion.

It contains a 7.25-square-inch viewing port and five different auto-darkening welding filters, the best of which offers up to 16 UV/IR protection. The bright state of the helmet is four, while the dark condition is nine through thirteen.

Two sensors are located beneath the solar panel. ArcOne 5000V-1171 Python Welding Helmet has a greater space between the inner and outer lenses, which helps to reduce heat transmission. If you weld too close to the arc in this manner, your lenses will not be fried.

Smoke and vapors have a hard time getting inside due to its circular shape. There is enough room for a respirator. It has better headgear and weighs less than 2 pounds, making it very comfortable.

The face shield should not be worn below 0°C (32°F). However, it can be used in temperatures as high as 55°C (131°F).

Pros

- Durable.

- No need for batteries.

- Cool looks.

- Light and comfortable.

Cons

- Moderate price.

3. Instapark ADF Series GX990T Auto Darkening Welding

- Four arc sensors

- Auto-darkening filter

- Large viewing area (3.94″ x 3.86″).

- Solar-powered welding helmet

- External controls and modifications for darkening

- Sensitivity, and delay are now available without having to remove the helmet.

- variable shade from 5 to 13, with a resting shade of 4

- 1/30,000 second bright to dark time

- For maximum protection, consistency, and comfort, this helmet is made of a

- Helmet is made of a lightweight composite material

Instapark ADF Series GX990T Auto Darkening Welding is most likely one of the cheapest helmet on the internet. The blue demonic appears old and grand in a welding environment. This is one of those facial guards that costs less than $100 but has three times the features.

The large view measurements are 3.94 x 3.86, which are similar to Lincoln welding helmets. It has four sensors, which is useful for TIG welding, and it has low amperages. The shade adjustment from 5 to 13 is handy for low amperages.

You may change the time from bright to dark in 1/30,000 seconds. Instapark ADF Series GX990T is also solar-powered, with three replaceable batteries. All of the controls (grinding button, sensitivity adjustment, and shading control) are located on the outside of the helmet, so you won’t have to remove it to use them.

It has enough room for a respirator and is rather light. People have complained about how uncomfortable. You’ll have to be careful with it and contemplate replacement parts if you buy it because it’s not very durable.

Pros

- Inexpensive.

- Big display.

- 4 sensors.

- Controls on the outside.

Cons

- Easily breakable headgear.

4. Jackson Safety Insight Variable Auto Darkening

- viewing area of 3.94″ x 2.36″

- 4 sensors to reduce possible blockage

- Lightweight Insight Welding Helmet

- variable shades from 9 to 13

- user-friendly digital controls for sensitivity

- Allow to use it for MIG, TIG, STICK, and ARC welding

- premium 370 Speed Dial easy grip/turn headgear

Jackson Safety Insight Variable Auto Darkening is Another Custom welding helmet with nearly all of the features of more expensive helmets at a fraction of the price. It has great American stars and stripes motifs as well as a simple but elegant decorative theme.

This high-quality lens has a large field of view (3.93′′ x 2.36′′) with a variable shade (9-13). It has four independent auto dimming sensors as well as user-friendly digital controls. I admire how well solar cells and batteries were integrated.

Many auto-darkening helmets use these popular coin-style batteries. It’s made of Nylon 66, a durable, flexible, and lightweight material. Inside, there’s enough space for a little respirator.

jackson Safety Insight Variable helmet is simple in design, yet it functions well, is comfortable, and stays put. The fact that all of the buttons are on the inside is something I don’t like. Because of this, replacing the front cover for the lenses is difficult. To install the front lens, you must first remove the entire back darkening unit. Other than that, it’s an excellent Custom welding helmet.

Pros

- Inexpensive.

- Good display.

- 4 sensors.

- Made of quality material.

- Durable.

Cons

- All the adjustments and buttons are inside.

- The complicated process for replacing the front cover lenses.

5. DEKOPRO Solar Powered Custom Welding Helmet

- Viewing area 3.62″ x 1.65″

- Response time is 1/25000 sec

- protect against UV and IR radiation

- delay settings for adaptability

- shade range 9 to 13DIN

DEKOPRO Solar Powered is the most affordable custom welding helmet on the market, and it performs admirably. It has a stunning American eagle paint job if you want to show people how patriotic you are, or if you just like eagles.

It switches from light to dark in 1/25000 seconds when not in dark mode and protects your eyes with UV and IF protection. It meets ANSIZ87.1-2010 and EN3794/9-13 requirements with a 3.62″ x 1.65″ clear visor viewing area and two sensors.

DEKOPRO Solar Powered has a 9 to 13DIN shade adjustment range. It is powered by solar cells and batteries. It is lightweight (1 pound) and has room for a respirator.

Because it is not built of the best materials, dropping or throwing it while upset is not a smart idea. Replacement parts are also inexpensive. Temperatures below 0 degrees Celsius are not suggested for use.

Pros

- Inexpensive.

- Cool design, inexpensive replaceable parts.

- Meet the standards.

- Good for beginners.

Cons

- Small view size.

- 2 sensors.

- I don’t recommend it for some serious work with big amperages.

6. Antra AH6-260-0000 Auto Darkening – Most Popular Welding Helmet

- Lightweight

- viewing are 3.86×173 inches

- 4 Premium redundant arc sensors

- UV/IR Protection

- Interference Suppression Technologies

- Shade range 5 to 13

- externla knobe

Do you prefer to take issues into your own hands as a welder? I know a few of these people who would rather paint their hood than buy one for the sake of the paint job. Because of its price and qualities, the Antra AH6-260-0000 is Classic Series mask is a popular choice for bespoke paint jobs.

The mask shape, first and foremost, is excellent for painting, and its strong geometric components allow for a wide range of innovative designs. But what about the welding characteristics?

Despite being a low-cost option, the Antra AH6-260-0000 Auto Darkening provides more than enough power for most jobs. It’s a four-sensor auto-tinting hood that reacts in less than a half-second. DIN 5 to DIN 13 are the different shades, with DIN 4 being the lightest. The viewing area is quite huge, measuring 3.86′′X1.73′′.

It’s light, and the headgear is comfortable enough that, even if you wear it all day, your neck won’t feel fatigued at the end of the day. The helmet also includes an external knob for regulating the shade and grind mode, making life easier for welders.

The cheater lenses and hard hat adaptor, both of which are sold separately, fit within the hood as well. It runs on solar energy and disposable batteries as a power source. It also has a built-in passive filter that provides IR/UV protection at all times, with a shade level of 13.

Pros

- Inexpensive.

- Cool design – Perfect for Custom paint jobs

- Meets the standards

- Good for beginners and more demanding users

- Fairly large view area

- Lightweight

- Cheater lens support

- Made from high impact polyamide-nylon

- Outside knob

Cons

- Headgear could be better

- Instructions on assembly/disassembly are not easily understood

- The shell is not rated for industrial use so no heavy use is recommended

What Are The Best Welding Helmets In General?

While the helmets mentioned above are excellent candidates for commercially available custom paint job helmets, they fall short of top-of-the-line hoods from Optrel, 3m, and other manufacturers.

On a separate page, we’ve put up a detailed shopping guide for the best welding helmets. This is the place to go if you’re seeking for the best gear. We also looked at a few inexpensive options that could be altered, and we’ll show you how to make your own bespoke hood below.

How To DIY Custom Welding Helmet

Now that we’ve covered all of the best welding helmets on the market, let’s talk about how you may customize your headgear. Follow these simple rules to apply for your unique paint job and show the other welders who’s boss. Check out our article on welding helmet makeovers for more inspiration, where we highlighted some great designs from various welding helmet artists.

Are you ready?

1. Gather your materials

The first thing to keep in mind is that heating paint that isn’t heat-resistant can be deadly.

Poisonous fumes are revived when non-heat-resistant paint is subjected to high heat, making it unhealthy to breathe.

If you weld frequently, you’ll need heat-resistant paint. Acrylic paint should suffice if you just weld on occasion. However, heat-resistant paint is still recommended.

Heat-resistant paints

- Rust-Oleum Heat Resistant Paint (750°C)

- POR-15 High-Temperature Heat Resistant Paint

- Coatings for high-temperature applications (VHT)

Welders don’t need to be reminded of the significance of proper ventilation, but remember that safety comes first, so prime and paint in a well-ventilated area

Heat-Resistant Acrylic Paints:

- Rust-Oleum spray paint is a good option.

- Krylon Fusion is an excellent choice for plastics.

Other materials:

- Fire-resistant primer

- A wire brush, sometimes known as a wire wheel, is a tool for cleaning wires.

- sanding paper (400 grit or finer)

2. Disassemble Your Helmet

People will tape off areas they don’t want painted in practically any painting project. Disassembling your helmet, on the other hand, will make the job easier, with less mess and cost.

Although it may appear to be more work at first, you’ll be glad you took the time to disassemble your helmet. You’re likely to overpaint your lens or another vital component unless you’re an excellent painter. Your helmet will lose its sharpness if this happens, and isn’t that the point?

Helmets made for professionals, on the other hand, are not cheap. You’ll want to look after your helmet and make sure it’s in good functioning order. Right? Right. As a result, disassemble your helmet and store the fragile (and expensive) components safely.

3. Clean & Prime Your Helmet

After you’ve disassembled your helmet and secured the delicate components to the side, it’s time to clean it.

If your helmet has seen a lot of use, you may need to start with the wire wheel or wire brush. If not, a little sandpaper should do the trick.

4. Cleaning in a nutshell

First, sand away the protective plastic covering using 400 grit sandpaper. Your primer and paint will take the place of this protective coat. Make sure it’s smooth and free of dirt, stuck-on carbon, and other debris. It’s very important to clean around the edges. Moisture and grime can creep in and rip the paint off if the margins aren’t clean and smooth.

After that, clean it with rubbing alcohol to get rid of any lingering grease or grime. This also guarantees that nothing biological on the surface is living and might cause your paint to peel, grow, or bubble. Then wipe it down with a dry paper towel.

Finally, give it a final polish with the wire brush. The primer and paint will stick to the surface as a result of this. You can skip this step if your helmet already has texture.

Then you may get your helmet ready. This step may not seem important to some, but it will help protect your helmet and increase the life of the paint job. If you like, you can skip it and go directly to painting.

If you do decide to prime it, give it at least 8 hours to cure before painting it.

5. Paint Your Helmet

Congratulations. You’ve arrived at the most pleasurable stage of the process. First, apply a clear coat, preferably one with a neutral hue (white or grey). Allow the neutral paint to dry completely before adding your chosen color.

6. Let Your Custom Welding Helmet Dry

Finally, use a hat rack, helmet stand, or something similar to hang your newly personalized helmet. Place it somewhere where dust and debris won’t fall on it. Set up some light stands and cover them with a tarp if you can’t find a dust-free place.

After that, all you have to do is let it dry for 12 to 24 hours before you can weld in style.

Conclusion

The most vital piece of safety equipment, the welding helmet, not only protects the face and eyes but also allows wearers to personalize their badass welding gear. Most welders are experimenting with auto-darkening helmets because they are concerned about having to constantly flip the helmet up and down in order to keep the MIG gun, TIG flame, or electrode in the proper position.

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.