This article will go through the reviews of the best multi process welders. Let’s Explore!

You can save time, money, and space with multi-process welding machines.

This is achieved by combining many welding processes into a single box.

However, you’ll need the correct set of procedures to create a meaningful difference in your shop.

And where do you look for someone who can labor all day for a reasonable price?

In this post, we’ve compiled a list of the best multi-process welders, as well as a buyer’s guide.

Top 8 Best Multi Process Welders

Without further ado, here are the best multi-process welders.

- Hobart Multi Handler 200 Multi Process Welder

- YesWelder MIG-205DS Multi-Process Welder

- Lincoln Electric MIG 210 Multi-Process Welder

- Lincoln Electric LE31MP Multi-Process Welder

- Forney Easy Weld 140 Multi-Process Welding Machine

- Weldpro MIG200GDsv MultiProcess Welder

- Eastwood Elite MP200i Multi process

- Vulcan OmniPro 220 Multi Process Welder

Best Multi Process Welders Reviews

This post will go through the features and benefits of the best multi-process welders that will undoubtedly prove their worth if purchased.

We’ll also go over the pros and cons of each welder so you can figure out which one is ideal for you.

Let’s get into the in-depth reviews of the best multi-process welders.

1. Hobart Multi Handler 200 Multi Process Welder

Key Features:

- DC, TIG, Stick, and MIG

- A 20-200 amp range is available

- Steel 3/8-inch to 24-gauge sheet

- The duty cycle is 30%

- Quickly selectable drive system

Overview

Hobart’s Multi Handler 200 Welder is the company’s first public-facing multi-process machine. If you prefer the Miller 215 but can’t afford it, the Multi Handler 200 is a suitable option. This device is dual-voltage, meaning it can run on either 120 or 240 volts. It has an all-metal wire feed drive that can handle wire spools with a diameter of 4 or 8 inches.

The power output of the Multi Handler 200 ranges from 20 to 200 amps. In MIG and flux core mode, it welds from 24-gauge sheet metal up to a 3/8-inch thick steel plate. In stick mode, the smallest thickness is 16 gauge, with the same 3/8-inch top-end capability. TIG mode is in the midst of the other ranges, with a material range of 22-gauge to 3/16-inch steel.

Hobart Multi Handler 200 Multi Process Welder also has a 12.5-foot TIG torch included but no foot pedal heat control. It does, however, feature a plug-in interface for a Hobart foot pedal that may be purchased separately. Because it’s a DC TIG machine, it’s not designed to weld aluminum, but you may use the optional Spoolrunner spool gun to do it in MIG mode. A 10-foot lead is provided by both the MIG gun and the stick welding electrode holder.

Pros

- Miller 215 is a fantastic substitute

- There are two voltages available: 120 volts and 240 volts

- Spools of 2 and 10 pounds can be loaded

- Get your spool gun ready

- It’s simple to use with only two knobs

- A TIG torch is included in the kit

- The TIG regulator is not included

- There isn’t a TIG foot pedal to be found

2. YesWelder MIG-205DS Multi Process Welder

Key Features:

- Dynamically arc adjustment

- 2T/4T trigger lock

- It has a modest footprint

- The voltage is divided between 120 and 240 volts

- MIG, flux-core, DC TIG, and stick

Overview

The YesWelder MIG-205DS Multi-Process Welders digital control panel is protected from the welding environment by a flip-up plastic dust cover. The machine’s 2T/4T trigger lock, which eliminates hand fatigue, makes long welding runs easier. Dynamic arc control with synergic settings can monitor the arc while you’re welding, altering parameters in real-time and updating settings on the fly to produce a better arc.

With this welder, you may do MIG, TIG, stick, and flux core procedures all in one box. It’s as simple as pressing one digital button on the control panel to switch between procedures. You’ll need a TIG burner to utilize the DC TIG, but if you have one, it’s simple to set up. Because it’s a DC TIG, the YesWelder MIG-205DS Multi-Process Welder can’t TIG or utilize a spool gun for MIG aluminum operations, but it can stick weld metal with aluminum welding rods.

With a wide output range, the YesWelder MIG-205DS Multi-Process Welder can weld materials as thin as 24-gauge sheet metal and as thick as 1/4-inch steel. The option of 120-volt or 240-volt energy rounds out a fantastic set of features with plenty of power at a moderate price.

Pros

- This is a good value for newbies

- The LCD screen is really bright

- Start-up lift on a TIG arc

- You may switch modes with a single button press

- It is barely 33 pounds in weight

- The front panel’s cover is flip able

Cons

- I’m unable to use a spool gun

- There isn’t a TIG torch included

3. Lincoln Electric MIG 210 Multi Process Welder

Key Features:

- 120/240-volt dual input voltages

- A connection for a 10-foot torch is provided

- Color LCD display

- DC stick, MIG, DC TIG, Flux-Cored

- 3 Years warranty

Overview

The Lincoln Electric Power MIG 210 MP is a versatile and powerful machine. With outputs ranging from 20 to 140 amps on a 120-volt input and 210 amps on a 240-volt input, it supports MIG, DC TIG, DC arc welding, and flux core welding procedures. You can weld as thin as 28 gauge with MIG with flux core at 20 amps and much thinner with TIG. You can utilize a 5/16-inch thick steel plate with a 240-volt input and 210 amps, on the other hand.

This machine’s wire feed spindle could be out of round, resulting in jams when the wire won’t feed smoothly. This is due to a warranty issue. Lincoln will replace it, but you must register your claim while the machine is still under warranty from the manufacturer. The only other severe problem is the lack of a TIG heat control pedal.

On the other hand, Lincoln Electric is known for its superior build quality and longevity. The Lincoln PowerMIG 210 MP Welder continues these traditions, and this multi-process welder comes with a three-year warranty from Lincoln.

Pros

- Onscreen setup is simple

- The 20-220 amp range is quite wide

- It has a gas regulator built-in

- Nozzles for MIG and flux core welding are included

- For gas, there is an internal solenoid

Cons

- The drive spindle is sometimes out of round

- It doesn’t come with a TIG torch

4. Lincoln Electric LE31MP Multi Process Welder

Key Features:

- 30-140 amps of welding power

- The input voltage is 120 volts

- A cast aluminum gearbox is used

- A brass torch is connected to another brass torch

- 3-year warranty

Overview

The Lincoln LE31MP welder is a high-powered multi-process welding machine. It has a robust aluminum adjustable gear-driven wire feed that can take 1-pound or 10-pound wire spools. An inbuilt gas solenoid regulates gas flow when you pull the trigger for TIG use. An external MIG gas regulator is included with the LE31MP multi-process welder.

There are almost no negatives to this versatile equipment, which can conduct gas MIG, DC TIG, stick arc, and flux core welding. One disadvantage is that in order to use the LE31MP’s highly regarded TIG process, you must purchase a TIG torch and a heat control pedal separately. Another concern is that it is built in Mexico, despite its excellent build quality, and thus fails to meet the Buy American criterion of various government contracts.

The machine’s welding quality and construction are praised by users, who like each process it does. It can handle everything from 24 gauge sheet metal to 3/16-inch thick plates, with a power range of 30-140 amps. Lincoln offers a three-year warranty for the LE31MP welder.

Pros

- The wire drive can be adjusted

- There is a gas regulator integrated

- Drive tension indicator

- In 24 gauge sheet, up to the 3/16-inch plate is possible

- Internal gas solenoid for TIG

Cons

- TIG torch and pedal are available separately

- Not made in the United States of America, but in Mexico

5. Forney Easy Weld 140 Multi Process Welding Machine

Key Features:

- DC TIG & Stick, MIG welding

- Adjustable controls that can be changed

- The output ranges between 10 and 140 amps

- The entire drive is comprised of metal wire

- A 10-foot MIG connection

Overview

Because it uses 120-volt input power, the Forney Easy Weld 140 is a high-quality multi process welding equipment that can do MIG, flux core, DC stick, and DC TIG. It can be used just about everywhere that has a house current available. The wire feed drive of this machine is made entirely of aluminum, and it can handle wire spools weighing between 2 and 10 pounds.

The electrode clamp and 10-foot torch connection provide you a lot of versatility in where you can place the machine in the work area, allowing you to move around and get more done. The MIG process requires the purchase of a gas regulator, which is one downside of this machine. The TIG process is the same, except it requires an additional torch, electrodes, and gas mixture.

With a spool gun and infinitely adjustable wire feed speed and amperage settings from 10 amps to 140 amps, the Forney Easy Weld 140 can apply these methods on sheet metal as thin as 32 gauge on up to 1/4-inch plate steel or MIG 1/8-inch aluminum. Forney offers a one-year warranty for the Easy Weld 140.

Pros

- This container can hold 2 pound and 10-pound rolls

- From 32 gauge sheet, welds up to the 1/4-inch plate

- Adjustable controls that can be changed endlessly

- Generators easy to use

- In the Tweco style, a MIG gun

Cons

- A gas regulator is not included

- TIG requires more components

6. Weldpro MIG200GDsv Multi Process Welder

Key Features:

- MIG, stick, and TIG welding

- Dual-display digital

- 120/240-volt input voltages

- An IGBT inverter’s output power

- 2 year warranty period

Overview

The Weldpro 200 Multi-Process welder can do TIG, MIG, flux core, and stick arc welding. The all-metal aluminum drive on this machine ensures a precise, long-lasting wire feed. Both 2-pound and 10-pound wire rolls can be fed using the feed mechanism. The inverter-type IGBT power source accounts for the machine’s 30-pound weight.

TIG is a lift-type arc start that uses a 2T/4T locking trigger mechanism to maintain the arc lit for long welding sessions. To use the machine in TIG mode, you’ll need to acquire the proper gas regulator. There is no foot pedal heat control in TIG mode, and this machine is incompatible with one. The Weldpro MIG200GDsv Multi Process Welder comes with a MIG-type gas regulator. The machine comes with torches for both TIG and MIG operations.

The Weldpro MIG200GDsv Multi Process Welder has a 40 to 200 amp output range with dual 120 and 240-volt input power. To keep arc power when welding, it incorporates automated speed and amperage correction. Weldpro offers a 2-year warranty on this product.

Pros

- Torches for MIG and TIG welding are supplied

- It is possible to mount both 2 pound and 10-pound rolls

- TIG arc starts with a lift

- The kit includes a MIG gas regulator

- 13-foot TIG connection

Cons

- The use of a TIG foot pedal is not permitted

- TIG welding requires a gas regulator, which is not included

7. Eastwood Elite MP200i Multi process Welder

Key Features:

- MIG, TIG, and stick welding

- There are dual volts on the input

- A spot weld timer

- The wire drive is entirely constructed of metal

- Weight: 34 lbs

Overview

The 30-amp breaker circuit on the Eastwood Elite MP200i Multi-Process Welder can be hooked into either 120 or 24 volts. This professional-grade welding machine supports MIG, TIG, and stick welding. On 120 volts, the MIG and TIG rated at 90 amps, while the stick moderated at 70 amps. On 240 volts, MIG and TIG reach 200 amps, while MIG and TIG stay at 170 amps. If you require more power, choose Eastwood’s Elite MP250i, which is designed for professional shop use, includes casters, and boosts the top-end punch.

From 22 gauge sheet metal, this machine can weld up to 3/8-inch steel. The Eastwood Elite MP200i Multi-Process Welders computerized readout makes keeping track of your output numbers a breeze. The knobs on the settings can be adjusted forever. Because it’s a DC TIG machine, it’s not meant for TIG welding aluminum, but Eastwood does provide an optional spool gun for MIG welding metal.

With 10-foot connections, the Eastwood Elite MP200i Multi-Process Welder comes with a TIG shielding gas regulator, a Trafimet ERGOPLUS 24 MIG gun, and a WP-17v TIG Torch. The arc welding electrode clamp has a 13-foot length.

Pros

- A gas regulator is included in the package

- Trafimet EP24 MIG gun

- WP-17v TIG torch

- Spools with a diameter of 4 and 8 inches are compatible

- The spool gun (optional)

Cons

- Stratch start TIG

- There isn’t a foot pedal

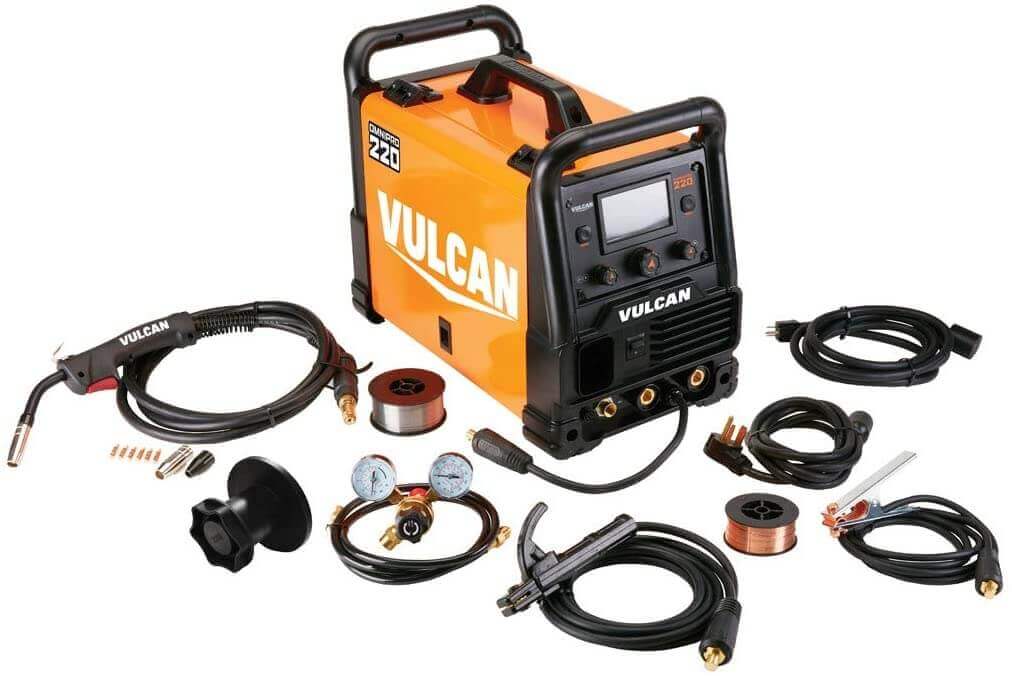

8. Vulcan OmniPro 220 Multi Process Welder

Key Features:

- Full-color LCD display

- Voltages range from 10 to 220 volts

- MIG/flux-core, DC TIG/stick

- Aluminum die-cast drive

- There are two voltages available: 120 volts and 240 volts

Overview

The Vulcan OmniPro 220 Multi Process Welder comes with a 4.3-inch color LCD screen. A built-in automatic setup option is also included with this welder. From the drop-down menus, choose your process, material type, and thickness. You can still modify or create your own settings, and this machine will remember them for future usage.

DC TIG and stick welding, as well as MIG and flux core welding, are all possible with this machine. The Vulcan OmniPro 220 Multi Process Welder welds 24-gauge sheet metal up to 1/8-inch steel on 120 volts and 3/8-inch steel on 240 volts. If you want to do TIG, you’ll need a torch, pedal, and regulator. Because it’s a DC-only welder, it’s not suitable for TIG on aluminum, but you may use the optional spool gun with the MIG process.

The Vulcan OmniPro 220 Multi Process Welder is popular among owners because it is innovative, versatile, and well-made. Memory, automated settings, and a color screen aren’t all that common, especially at this price point. There are 132 predefined settings programs at Harbor Freight, as well as the option to save your own.

Pros

- Get your spool gun ready

- Getting memory settings back

- There are 132 applications already installed

- Automatically generated settings

- Steel ranging in thickness from 24-gauge to 3/8-inch thick

Cons

- A TIG torch or a pedal is not available

- DC TIG can’t use for aluminum

A Buyer’s Guide

We’ve put together the definitive buyer’s guide to help you find the best multi-process welders.

Some of the reasons why multi process welders are advantageous are as follows:

1. Several treatments can save you time and money right now

2. You can save space by combining several machines

3. It is less costly than purchasing a number of single-purpose machines

Multi-process welding machines help small fabrication firms, car body shops, and home DIY craftsmen alike.

One-man operations can save a lot of money by employing just one main and backup equipment, which is still cheaper than purchasing a whole set of specialized gear.

Which Features Are You Looking For?

There are no single criteria that determine which welding processes are covered. Some have only MIG and stick processes, while others have TIG, flux core, and MIG processes, as well as a plasma cutter.

TIG is, without a doubt, the best sheet metal welding process. Sheet metal can be worked with using both MIG and flux core, but only if the arc can be easily controlled and the minimum output is less than 20 amps. TIG welders that run at less than 5 amps are preferred by many sheet metal craftsmen.

When welding thick steel plates, stick arc, and MIG techniques provide the best penetration. Plasma cutters can be quite beneficial to fabricators. You save a lot of money on labor when you only have to flip a couple of switches and attach a torch to cut metal right where you’re working.

Saving that step across the shop to pull a cut over the course of two machines adds up to significant savings.

What Is The Main Process?

Any welding power source can be used to run practically any process due to the nature of welding technology. It’s easy to observe how high-end machines with a lot of processes and settings differ from machines with only two processes and basic settings. One is more costly.

You must choose the most crucial welding processes. To keep costs down, each manufacturer will focus on one basic welding mode. Make sure the principal function of a machine corresponds to your priorities.

Handle you need to do a lot of heavy-duty welding, cut quickly, and be mobile? A plasma cutter and a MIG or arc welder are required.

If you don’t regularly cut, a multi-process machine with MIG, TIG, and stick instead of a plasma cutter may be more cost-effective.

Recommended Post: Best arc welders

What Type of Work Do You Do?

You’ll need an AC TIG welding machine if you want to TIG weld metal. On aluminum, AC TIG machines generate the best-looking and most lasting welds.

Flux core or stick arc approaches should be your first choice if you want to do a lot of outside work.

Extras And Accessories

If you don’t already have a TIG or MIG torch, or if you need a heat control pedal for a TIG machine, bear that in mind while comparing prices. Certain machines offer features like lift-type arc starts, or high-frequency no-touch arc starts for plasma or TIG electrodes. These features help you save money by delaying the depletion of consumables. You may discover that you don’t require dual voltage input and may get by with only 120 volts.

Which Option Is The Best For You?

For most welders, the Eastwood Elite MP200i is the best option and value. It offers a lot of cool features, a solid set of attachments, good build quality, and Eastwood’s 3-year guarantee, which can be extended for an extra two years for a price.

The Hobart Multi Handler 200 Welder gives you big-name peace of mind with a five-year guarantee and the Hobart reputation for customer care. Along with a vast nationwide dealer and service network, you get massive power, spool gun capabilities, and the option of installing a foot pedal for TIG work.

The YesWelder MIG-205DS welder is our budget selection for a multi-process welder with 200-amp MIG, TIG, flux, and stick power. It includes amazing design features such as a flip-up front panel dust cover and single-button switching for ease of use. It’s versatile, offers dynamic arc settings, and packs a punch for the money.

Conclusion

Some of the best multi-process welders are included in the list above. However, if you want to know which one is the best all-around, we’d have to choose the YesWelder MIG-205DS welder.