Do you want to own the best spot welders? Spot welding is a welding technique that uses pressure and an electric current to join overlapping metal components. The thickness of metals that can be spot welded ranges from 0.02 inches to 0.118 inches. The pressure point applied by the copper electrodes provides a steady welding point.

The basic equipment required for spot welding is the workstation, which includes the welding power supply and the weld head, to which the welding electrodes are attached. Because of their high conducting qualities, copper welding electrodes are employed.

You’ll need a spot welder if you need to join two metal sheets together. You’ll need certain tools to help you with all of the time-consuming procedures, especially if you’re welding together a large number of little pieces. Spot welders are a professional tool that welding professionals use, yet they are not difficult to learn and master. Learning spot welding, or welding in general is best done under the supervision of a qualified welder.

There are various safety standards that must be followed to the letter in the welding profession. But have no fear: welding is a skill that anybody can master. Anyone can learn to weld, even if it’s simply for home maintenance. If you put your heart, effort, and time into it, you, too, can learn to weld.

There are many different types of spot welders, so learning more about their specifications and features can help you make an informed selection when choosing one for your individual needs. Choosing the right instrument for the job might be tough, especially if you have to limit the salesman’s selling powers and zeal.

For both the DIY enthusiast and the professional welder, we’ll look at some of the best spot welders.

Top 5 Best Spot Welders

Below is the list of the best spot welders:

- YaeCCC SUNKKO 719A Weller Soldering Pencil

- Stark Professional Portable Spot Welder

- Tooluxe RIDGE 10915L Professional Spot Welder

- Lenco Autobody Dual Spot Welder

- Mophorn 737G Pulse Spot Welder

Best Spot Welders Reviews

This post will go through the features and benefits of the best spot welders that will undoubtedly prove their worth if purchased.

We’ll also go over the pros and cons of each welder so you can figure out which one is ideal for you.

Let’s get into the in-depth reviews of the best spot welders.

1. YaeCCC SUNKKO 719A Weller Soldering Pencil

Key Features:

- The dimensions are 8 x 5.8 x 1.4 inches

- The weight is 11.2 ounces

- 110 volts from the power supply is required for operation

- Output: 500 Amps

The Sunkko from YaeCCC spot welder is a lithium-powered welding pencil. Sunkko soldering pencils work with the 709 series of Sunkko spot welders. The soldering pencil must be connected to the power supply via the connector, which must be connected to the cables with the screws provided. It must be securely linked to the welding power supply for safe operation. The welding nozzles can be simply replaced if they get damaged.

To make this pencil operate, you’ll need to plug it into a desktop power supply. The soldering points are easy to remove and replace. The Weller soldering pencil comes in a convenient, interchangeable case. This welding pencil is suitable for a wide range of tiny and mobile applications.

Because it is a small spot welder, the Sunkko spot welder is only capable of welding thin metal sheets. The welding needle is composed of an aluminum alloy for long-lasting performance, and the pencil has an anti-skid foot for increased comfort.

Pros

- Working with it is simple

- Welding nozzles that can be swapped out quickly

Cons

- The 709 series is the only one that works

- It must be plugged into a power outlet

2. Stark Professional’s Portable Spot Welder

Key Features:

- The dimensions are 4 x 10.6 x 5.7 inches.

- Weight: 29.1 pounds

- Input voltage: 120/240 volts

- 2.5 kVA of power output

- The duty cycle is 50%

Welding a range of materials is straightforward with this single-phased spot welder. The Stark Professional Portable Spot Welder welds a variety of materials with ease, speed, and strength, including various grades of steel and cast iron. The basic design of the welding mechanism makes it simple to input the material that has to be welded together quickly.

Because of the simple press and weld system, it’s simple to complete many works in a short length of time. The bag includes a handle on the top that makes it easy to pick up and move about.

For beginners, this Stark portable spot welder is ideal. Because of how simple it is to use, it is an excellent instrument for novices to learn the trade. It’s not just for unskilled welders, though. The Stark is a professionally constructed spot welder for the on-the-go licensed welder. For the price, it’s also a terrific option for beginners and do-it-yourselfers.

This is a safe tool that can be used by anyone. The quick clamp and release motion makes it simple to apply the correct amount of current and timing in a safe manner. This portable spot welder’s air-cooled design keeps it from overheating while in use.

You will receive an additional set of tips when you purchase the Stark spot welder. The suggestions can be put to a variety of uses. With a vigorous pushing action, the 6-inch long points lock firmly into the materials to be welded, providing a solid bonding basis for a successful connection.

If necessary, the tips can also be easily removed. Twist off the old tips and screw on the new ones when it’s time to replace them.

The Stark is especially well-suited to hard-driven spot welding. The welding tips are composed of high-quality steel to ensure that you receive a perfect weld every time you use it. You may swiftly and easily press down the lever and conduct the spot weld thanks to the simple lever mechanism and ease of usage.

It’s easy to see why the Stark portable spot welder is a favorite among novices and professional welders alike when you consider the simple clamping and spotting mechanism, as well as the ease with which you can quickly operate it.

You will not be bound to a particular location because it is a portable spot welder. You can perform many jobs even in remote locations and bring the Stark with you.

The professional appearance and structure of the Stark spot welder provide a solid basis for getting the welding done quickly and reliably for every spot on the material.

The Stark can weld a variety of materials with thicknesses ranging from 0.118 inches to 0.118 inches. The Stark spot welder can spot weld mild uncoated steel, galvanized steel, and stainless steel sheets, among other materials.

Pros

- It’s easy to use

- Quick press and release mechanism

- Able to deal with a variety of materials

- Exceptionally well-made and long-lasting

Cons

- It’s a little heavy for a mobile spot welder

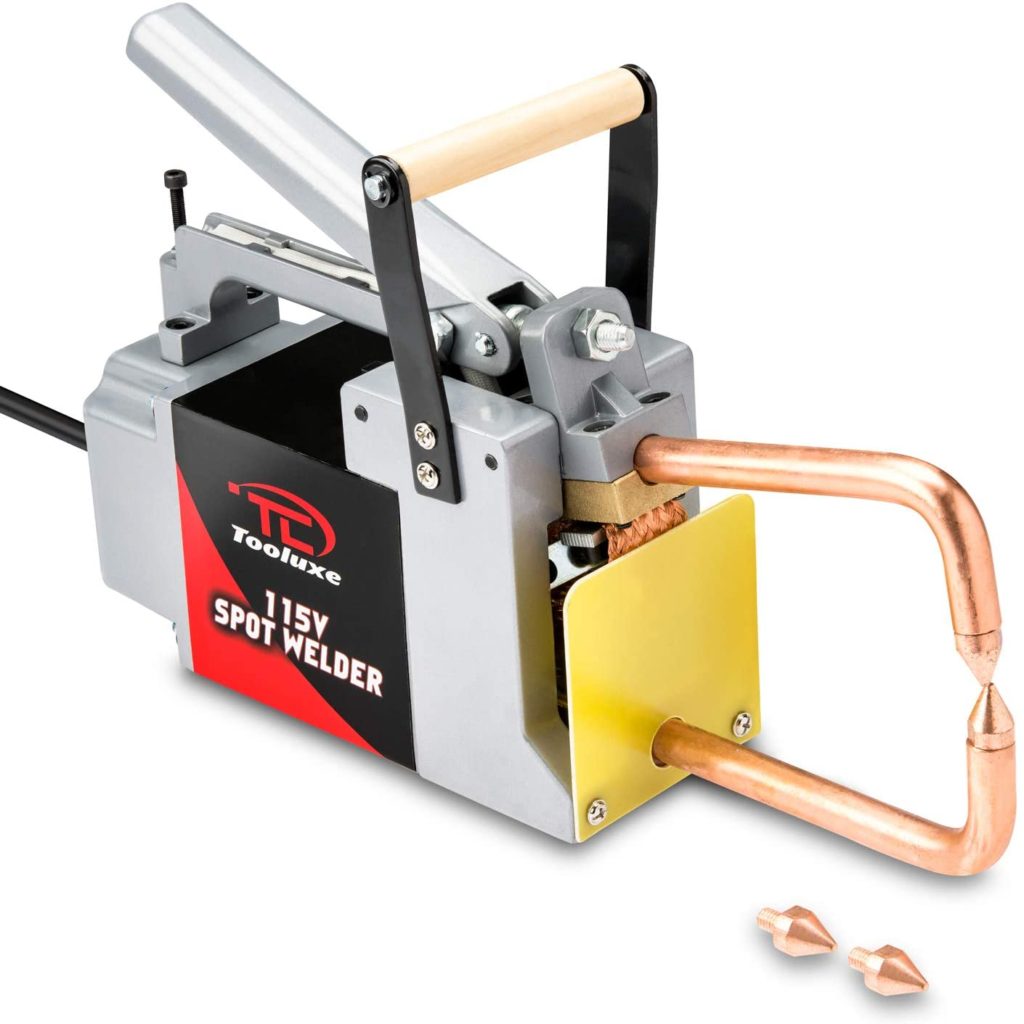

3. Tooluxe RIDGE10915L Professional Spot Welder

Key Features:

- The dimensions are 20.5 x 6.1 x 10 inches

- Weight: 34 lbs

- The input voltage is 115V at 60Hz

- The output is 125 amps

- The duty cycle is 30 percent at 6.6kw

The Tooluxe electric welder is another portable spot welder for commercial use. The Tooluxe is a true portable welder with a convenient attached handle for easy pick-up and transport, but it is a little heavy at 34 pounds.

Unfortunately, if you have a busy schedule and several portable jobs, the extra weight may exhaust you. It’s still better to be able to take your spot welder with you everywhere you go. The Tooluxe portable welding machine is a versatile tool that can connect a wide range of sheet metals.

This Tooluxe professional spot welder is an easy-to-use welding machine that is excellent for both beginners and professionals. For anyone interested in welding as a pastime or a profession, the Tooluxe is a fantastic instrument.

For beginners, the Tooluxe is an easy-to-use welding machine. It’s easy to use and set up for welding projects. It can spot weld metal sheets and be used to produce delicate jewelry.

The Tooluxe Spot welder is a simple-to-use welding machine that is quite safe to use as long as you stay below the acceptable operating limits. The single-phase option makes it safe to use in the house for the DIYer and rookie welder.

When you acquire the Tooluxe Professional portable spot welder, you’re receiving a welding machine that’s well-made, strong, and durable. It provides you with a machine capable of handling a large amount of work.

The welding tips are made of high-quality steel to enable a perfect and reliable welding connection for materials with a thickness of up to 0.039 inches. The 6-inch welding tips give a firm grip, allowing you to apply the necessary pressure to produce a strong welding bond between the materials to be welded.

This machine will help you achieve your aim of completing high-quality welding projects on time. This is a combination of a professional instrument and a powerful spot welder.

The Tooluxe Ridge Professional portable welder is made for heavy-duty and general spot welding on a variety of materials. Because of the ease with which it can do the operation, this tiny equipment is ideal for all-around spot welding.

Because spot welding techniques are so straightforward with the Tooluxe, it’s a terrific choice for both novices and professionals. It can also be utilized for any necessary DIY repairs. Because it’s so easy to pick up the spot welder and transfer it to the next area, it’s great for portable jobs and on-site repairs. Even if you are not exceptionally strong, transporting it will not be difficult.

The solid and durable build of the Tooluxe professional portable spot welder makes it a good, dependable piece of equipment for enabling you to conduct expert metalwork anywhere. When it comes to metal welding, the Tooluxe’s clamping mechanism’s rapid push and release motions provide you an advantage over the competition. The high pressure of the welding tips will provide a robust weld every time.

The Tooluxe can spot weld a variety of materials for faultless metal sheet bonding that is long-lasting, if not permanent. The Tooluxe can readily fuse stainless steel, as well as mild and carbon steel. Remember that you can weld uncoated galvanized steel sheet metal with the Toolux Ridge professional portable spot welder.

Recommended Post: Best Stud Welder

Pros

- With ease, handle and operate

- Quality, strength, and sturdiness were all taken into consideration when designing this product

- The pressure exerted by the tips is considerable

- Overall, it was a quick and easy process

Cons

- The duty cycle is really low

- Heavyweight

4. Lenco Autobody’s Dual Spot Welder

Key Features:

- The dimensions are 9 x 3 x 2 inches

- The weight limit is 110 pounds

- Input voltage: 208/230V

- Output 60/50A

This Lenco spot welder delivers a clean, consistent weld, making it ideal for professionals. You may set a timer for it to shut off, and it will shut down on its own. It does, however, take some time to become fully acquainted with the appropriate settings. This equipment is easy to operate; merely press the two electrode guns against the work, press the button, and the welder will do the rest.

There will be no additional costs because there are no wires, and there will be no flames or gasses to injure you. Of course, when utilizing a device like this, you should always exercise caution and keep safety in mind.

The features of the Lenco spot welder include a solid-state timer, a shielded control panel, and a sleek, streamlined design. This product is preferred by many welders since it is regarded as a high-quality option. Instead of clamps, it has two distinct arms that may be put wherever they are needed.

It should be noted, however, that this welder is not suitable for beginners; you need to have some prior knowledge before picking up and using this machine. Accuracy can be a challenge with this product because it lacks spot welding tips that can easily line up like other welders.

You’ll be able to combine body parts (non-human, of course!) faster and more easily with the Lenco spot welder than you can with gas welders. The reason for this is the smooth and clean welds you may expect from the product.

Unfortunately, not all retailers carry the components for this welder, so finding them may be difficult. If you’re looking for parts, you might be able to get them from an online seller if you look hard enough.

Pros

- Excellent quality product

- Flexibility

- Mobility is provided by the inclusion of wheels

Cons

- This is not a game for beginners

- A little costly

5. Mophorn 737G Pulse Spot Welder

Key Features:

- Dimensions: 9.1″x5.5″x8.3″

- Weight: 12 pounds

- Input voltage: 110V.

- Output: 50A-800A

If you’re on a tight budget and need a spot welder for minor work, this could be the best option for you. The Mophorn 737G Pulse Spot Welder is perfect for welding ultra-thin nickel-plated steel strips (0.03 – 0.2 mm) and is rechargeable lithium battery compatible.

The convenient LCD display screen will allow you to keep an eye on the current and pulse while you work. This product is great for anyone who has a few small tasks that need to be accomplished quickly and correctly. It will not, however, be able to use a welding pen.

The Mophorn Pulse Spot Welder is not advised for welding aluminum or copper. Nickel, iron, nickel-plated iron, and nickel-plated steel, on the other hand, operate well (and other alloys). Because of its limitations, the Mophorn Pulse isn’t extremely popular among users. However, some users have experienced success while welding stainless steel with this welder.

Other than the aforementioned alloys and nickel, it is not approved for use.

The Mophorn Pulse Spot Welder is an outstanding budget welder for welding how to utilize this type of equipment in general.

Unfortunately, according to certain internet evaluations, the Mophorn should not be used since the electrodes could be damaged. Due to its ineffectiveness, it regularly fails to meet expectations. You should be OK if you’re searching for something to do on occasion that requires very little work.

Recommended Post: Best Aluminum Welder

Pros

- Affordable

- This product is suitable with alloys and nickel

- The LCD Display is very practical

Cons

- Not very powerful

- It would be impossible to support a welding pen

Buyer’s Guide

Let’s take a look at some of the things to think about and information to keep in mind while choosing the best spot welder and making the most of it. If you consider this information when making your choices, you may discover that you make a better choice that better matches your unique needs.

Price

One of the essential elements in selecting whether to buy a spot welder or move on to the next product is, of course, price. Prices vary depending on the manufacturer and the spot welder’s capabilities. Make sure you’ve set aside enough money for these welders; they can be costly at times, but they’re typically well worth it.

Warranty

To guarantee that you are happy with your purchase, most businesses offer some sort of warranty. To avoid feeling like an idiot if something goes wrong, find out what kind of guarantee the welder you buy has.

What to Look Out For

Spot welders have the potential to be extremely trustworthy and generate high-quality welds, which is something we all desire.

In other cases, though, you may need to remove or damage solder joints. This is more likely to happen if you use your welder for projects involving auto repair or a lot of sheet metal with spot welds. This is where a skilled welder sets himself apart from the competition. You’ll be able to cut around the fix with ease, preserving a lot more original metal.

Spot Welding: What Is It and How Does It Work?

If you’re thinking about buying a spot welder, you should first learn how they function. It’s possible that you’re already an expert and knows everything there is to know. You may proceed to the following section if this is the case. If you are new to spot welding and want to understand as much as possible before getting started, you will benefit from what we have to say here.

Spot welding is used when you have two pieces of metal that you wish to join together to get a thicker piece of metal to work with. It’s a sort of resistance welding that involves joining two (or more) metal components together.

The majority of these welders are used in the automobile industry, but they are also useful for many hobbyists and small businesses. Spot welders are also occasionally utilized by artists to create unique works of art.

During welding, your welder will generate thermoelectric heat, which will be applied to the metal in circular patterns. Because copper alloy electrodes are good at passing electric currents, they are extensively used. Depending on the welder and the amount of pressure employed, the diameter of your welds will range from three to twelve millimeters.

The Advantages of Spot Welding

This process, like every other welding method, has benefits and drawbacks. Spot welding provides exceptionally durable welds, which is the most significant advantage (by most people’s standards). When long-lasting and trustworthy welds are required, spot welding is usually utilized.

- You won’t need any additional metal weld materials for spot welding because this procedure uses electrical currents that pass through the connected electrodes. All that is required is an electrical power source. Of course, if you’re motivated by the desire to save money on equipment, this will help.

- Because it doesn’t require a lot of heat, you won’t have to worry about scorching the remainder of the metal you’re working with.

- Because the instruments are so simple to use, spot welding is an excellent way for beginners to learn how to weld. This does not, however, remove the necessity for them to practice before doing large responsibilities. You must still be careful to use the welder correctly, or you risk making a mistake.

- Another reason that adds to spot welding’s appeal is its speed. Spot welders speed up your work and are portable, allowing you to carry them wherever you need to go as long as there is power.

Disadvantages of Spot Welding

- It’s worth mentioning that not all materials are appropriate for spot welding. The most common low-carbon steels that are easy to work with are titanium, nickel alloys, and stainless steel.

- In general, many people will find spot welders to be difficult to use. The electrodes’ position has a significant impact on how confined you are. Angles and unique shapes aren’t the best friends of spot welders.

Safety Precautions to Always Keep in Mind

Always read the user’s guide and safety instructions that come with your welding machine. This holds true for any and all sorts of welders on the market. If you follow the manufacturer’s recommendations and guidelines, you’ll be off to a good and safe start.

When you use a spot welder, the heat passes through the electrodes, exposing you to the risk of being burned and possibly starting a fire. Before placing electrodes on a potentially combustible surface, be sure they’re absolutely cool. Always remember that it’s better to be safe than sorry.

One of the first and most crucial principles to remember is to always wear gloves.

Spot welders, like any other welder, emit sparks, therefore wear proper eye and facial protection at all times. Never look straight into the light that a spot welder creates.

While welding, electrodes are prone to become trapped, and you’ll want to avoid this calamity. If the electrodes are not properly aligned or the force is too low, this can happen. Keep this in mind and double-check it frequently. Because a metal surface is quickly dirty, electrodes can also stick in a messy work environment. Make sure your workspace and equipment are clean before you begin welding.

Keep an eye on this while working because too much heat can cause electrodes to become stuck.

A wise precaution to take is to apply corrosion protection to the metal before welding it together. Bonders, sealers, primers, and final paint coats are all options. This will make your work much more manageable.

Test Alloys before Welding Metals Together

This is to confirm that the settings on your spot welder are proper. Before you start working, test two parts by welding them together and then destroying them with a hammer and forked chisel to determine if they’re properly welded. You can use this method to determine the strength of the weld.

What about Single-Sided Resistance Spot Welding?

Because spot welders are tough to handle and aren’t suitable for a variety of odd angles, you might be asking if you can use this procedure. However, this is not a practical option.

The double-sided method will be required in most cases. Only a limited percentage of the time does single-sided spot welding work. If you wish to use this approach, you may need to invest in a second welding machine.

Conclusion

Now that you know what goes into choosing the best spot welder and what to look for, you should be able to find the perfect spot welder for your needs. As long as you remember, everything listed here

In the end, the decision between a Stark spot welder and a Lenco dual spot welder comes down to what you want to use it for and how much you can afford to spend. However, such equipment is always an excellent investment, so you shouldn’t have any trouble parting with the cash once you’ve found the welder you require.

Also, be careful not to damage the welding machine or the welder who is using it. So, what are you waiting for? Go out and find that spot welder who will make your work easier, more robust, and reliable, using all you’ve learned here.

With 8 years of experience a senior welding instructor and safety equipment researcher and writes articles, reviews and guidelines on helmets and other welding and safety gears at Welder Choice, and other written works have been published in various publications.